3D Printing Glass Fixtures for Facades

![]()

Building glass facades help to create a smooth aesthetic for buildings, often concealing structure underneath to create something more visually fitting for the city where the building is being constructed.

But facades are not easy to mount on buildings. They often require mounting holes to be machined into the glass plate, and the holes can act as stress concentrators and can crack over time.

The other traditional ways of fixing facade glass into frames require some form of adhesive which can deteriorate under environmental conditions, such as UV light from the sun.

Either scenario can require replacement of panels as the fastenings deteriorate. If only there was some method of joining similar pieces of glass together additively…

Glass on Glass

The Glass Competence Center (ISM+D and MPA IfW) at the Technical University of Darmstadt, Germany has come up with a method of printing 3D glass features on float glass.

Float glass is made by floating molten glass on top of a pool of molten metal, traditionally tin or lead. This provides an incredibly smooth and flat glass surface which is used in a variety of applications, including windows and even flat panel TVs.

The team wanted to know if a joint of a similar material could be joined to the glass plate, minimizing brittle areas, ensuring the bond takes hold, and enabling the loads from the glass pane to be transferred predictably via the joint and into the mounting points on the building.

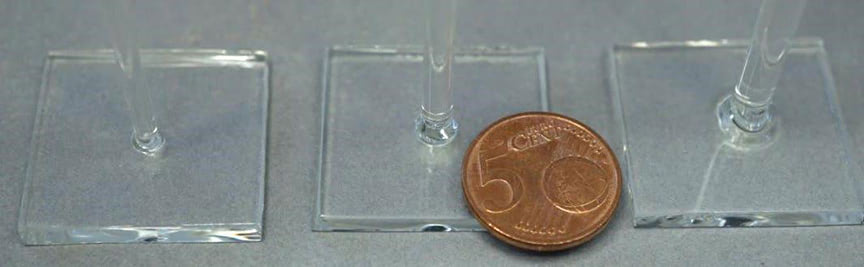

Naturally, this joining requires an application of heat to the glass bracket and also the joining faces of the pane itself. In order to join properly, the glass needs to be heated far above its transformation temperature. Heating it below that temperature will result in a poor bond (or no bond at all). Heating it too much can cause localized distortions and warping. Finding that sweet spot which preserves the join, the mechanical qualities of the system and the aesthetic finish, were therefore the main goals of this research. And you can see the results of one of these experiments in the image below.

The team experimented with a variety of glasses including soda-lime glass and also borosilicate-based glasses, and used some form of extrusion-based printer system, with a heated nozzle extruding tracks of molten glass onto the target, as seen in the example of the printed glass columns in the image above.

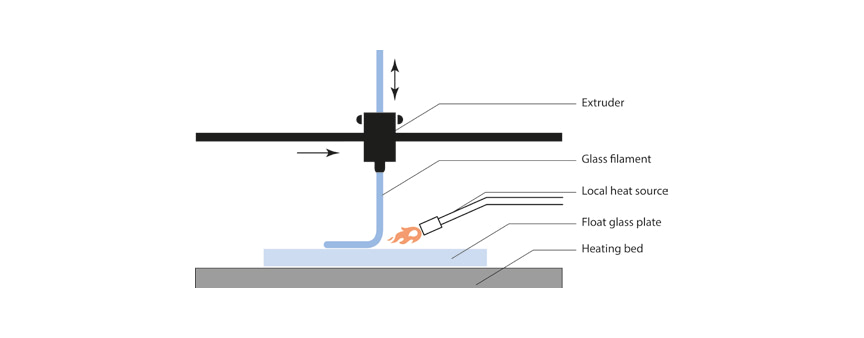

The university has stated that it is an FDM type process however, so one imagines a print gantry suspended over the vat of molten metal, depositing material onto the floating glass surface. While there are no images on the TU Darmstadt website, a quick Google search shows that the Darmstadt team have been working with TU Delft on this topic.

The image below is from another paper published jointly by Delft and Darmstadt, and seems to confirm this process. Note the heat source is separate from the print head, in opposition to traditional filament printing methods which hold the heater in the printer nozzle.

Other Glass Printing Methods

Glass printing is not a new phenomenon… researchers have been printing glass for at least 25 years. They seem to still be searching for that killer app though. Will it come in the form of printed fasteners? Maybe. They certainly offer cost savings, if the process is automated.

And that is the next step for the team: automation and repeatability. Now that the team has demonstrated that the process works, now it is a case of optimising the process and that will require automation.

And of course, simply automating a process does not mean the end of development…it may just be the beginning in fact. Glass used in architectural applications must not only be repeatable and homogeneous, but they must be tested for thermal shock and post-break behavior too.

But the foundation of the process has been demonstrated, and the research teams have some big names behind them (including Schott AG), so it seems only a matter of time before we see this technology hit the main stage (the glacial pace of AEC product certification processes notwithstanding).

Original Source: https://3dprinting.com/construction/3d-printing-glass-fixtures-for-facades/