5 Things You Should Know About SondaSYS SLS 3D Printers

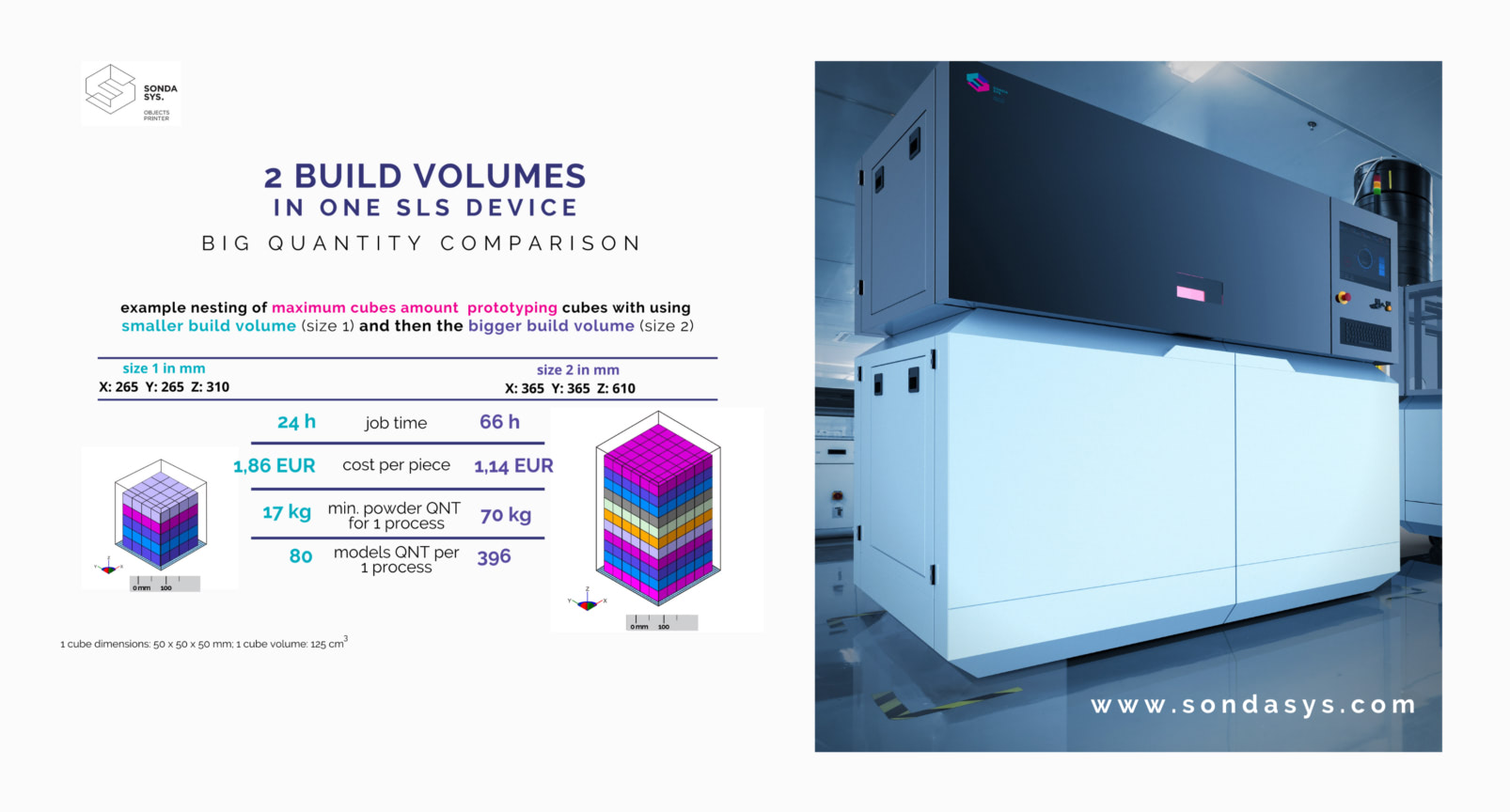

RECTIFICATION: This article was first published on June 5, 2020. In that publication we wrongly displayed the measurements of the two build volume options of the SondaSYS SLS 3D printer. The correct build volume for size option 1 is 265 x 265 x 310 mm. The correct build volume for size option 2 is 365 x 365 x 610 mm.

There are many industrial SLS 3D printers on the market, that’s for sure. Of course, some of them will meet your needs better than others. Polish manufacturer SondaSYS has developed a 3D printer that, despite being powered by the now-standard Selective Laser Sintering technology, is truly unique. So what makes it special?

1. The Build Volume Can Be Changed

That sounds great, but is it a hassle to change? Will I need to manually change build platforms? Nope, changing the build volume is completely digitally controlled. All changes are automated by the machine, so all you need to do is to choose size 1 (265 x 265 x 310 mm) or size 2 (365 x 365 x 610 mm). The printer will prepare the selected build volume by itself, including all of the galvo, laser, and heating parameters. If you need to print small objects or a small number of objects, then size 1 will be more efficient as the heating and cooling times will be shorter, the amount of powder needed will be less, and the cost per part will be lower. And when you need to print larger parts or lots of them, then size 2 is the way to go.

2. Military-Grade 3-Axis Optical Galvo

The galvo is incredibly important in SLS 3D printers as it directs and focuses the laser beam.

SondaSYS uses optical galvos from Cambridge Technology (bought by Novanta some time ago) that are high-enough quality that the US Army uses them in their guidance systems, and SondaSYS is the only 3D printer manufacturer using those galvos. The 3-axis optical galvo enables the changeable build volume, dramatically increases the speed of the printing process, and greatly improves print quality.

3. Dynamic Laser Beam Width

Much like the build volume, the width of the laser beam can also be changed, even during prints. Why is that important? The width of the beam determines how wide the sintering path is; a wider beam sinters more powder with each pass and thus increases print speed. Wider sintering paths also make for stronger parts because more of the object is solid. The tradeoff of using a wider beam is lower resolution of details. But the printer can change its beam width while printing, so the internal infill of an object can be printed with a wide beam where resolution isn’t important and the outside can be printed with a narrow beam to capture every detail. That way, parts print quickly and still look good.

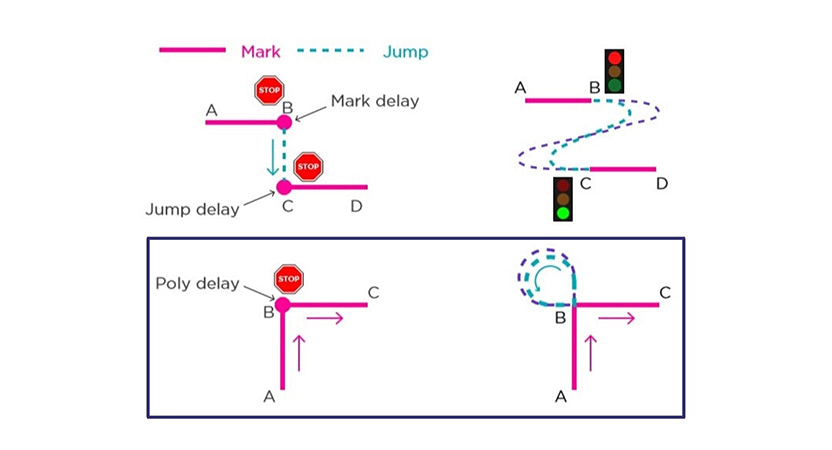

4. Skywriting

In a standard 2-axis galvo system, the laser dot moves to its destinations with irregular pauses due to physical limitations of moving the mirrors. Those irregular pauses cause some powder to become over-sintered, leading to imperfection on certain printed features, such as folds on sharp angles. In the SondaSYS SL02, the 3-axis galvo enables the laser to make arcing movements between points to dissipate excess energy without slowing down the print process. Additionally, the laser automatically turns on and off to maintain speed without burning powder. These advanced processes are controlled by the SondaSYS RP software and the algorithms of the Cambridge Lighting 2 system. Once the excitation and sleep time of the laser is calibrated during setup, it won’t need to be calibrated again.

5. Open Material Ecosystem

Not every material supplier charges the same for their powders so an open material platform allows you to choose the supplier that best suits your budget. Just as importantly, an open platform empowers research institutes and R&D departments to freely experiment with new and exotic materials, paving the way for better products and processes that can be used by others.

Sonda SYS. SL02

Features

- – Swappable build volume: 2-in-1 SLS 3D Printer

- – 3-axis galvo optical system by Cambridge Technology

- – CO2 laser by Synrad

- – Open to 3rd party materials

Original Source: https://3dprinting.com/3dprinters/5-things-you-should-know-about-sondasys-sls-3d-printers/