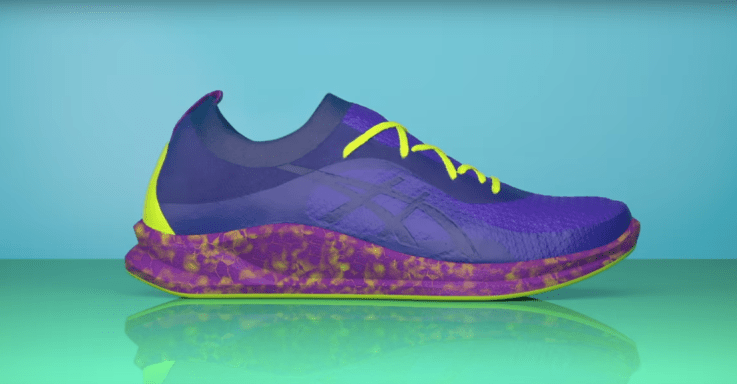

Asics is using microwave technology to create custom midsoles in as little as 15 seconds

It’s been a fascinating couple of years for high tech sneaker heads, between self-lacing Nikes and Adidas’ experiments with 3D printed midsoles and biodegradable yarn. Asics isn’t generally uttered in the same breath as those sorts of bleeding edge offerings, but the running shoe company has just debuted a pretty compelling new take on the manufacturing process.

The new technique, developed alongside Taiwan’s Tayin Research & Development Co., Ltd., promises customization, while offering up a relatively sustainable solution to shoemaking — two concepts that tend not to go hand-in-hand in the garment industry. According to Asics, the process utilizes heat generated by microwaves to fuse different materials together, in order to create the shoe’s midsole.

Asics is just offering a sneak preview of the technology at the moment, as it’s still in the testing phase — but if all goes according to plan, it could be rolled out to the point of sale. Somewhere down the road, the company plans to bring actual production microwaves to shops, so customers can select their custom shoe design in person. It’s not too dissimilar to the kind of customization Adidas is currently offering up in its New York flagship, but the whole shoe cooking process takes as little as 15 seconds to complete, which should cut significantly into your store browsing time.

That’s also significantly shorter than the 3D printing process many companies are currently exploring for their own shoes. And it apparently cuts the process’s energy consumption down by nearly 90-percent, compared to the company’s current midsole-making techniques.

For the time being, Asics isn’t offering much in the way of additional information, beyond the above visuals that look more like a Chuck E. Cheese ball pit than anything I’d like to put on my feet. Scalability is a pretty big open question, as well. The company say it’s going to bring it to “select footwear ranges in the future,” but as with 3D printing, it’s likely to stay more of a limited novelty, at least in the short term.

Keep an eye fixed out for underwater collectibles and money to get sweet

upgrades. One of the issues customers love about Roblox is that anybody

(teenager or older) can develop games (which Roblox refers to as “experiences”), and even receives a commission for it.

Though there are some shoot-em-up experiences

within Roblox, this isn’t one among them.

利生塔 – 楽音廃寺(三重県伊賀市佐那具町)に所在した。次いで、1920年代にラジオ放送が開始されマスメディアが音声を伝えることも可能になるとすぐに音楽番組が開始され、不特定多数の人々に一律の音楽を届けることが可能となり、音楽の大衆文化化が進んだ。 しかし、製造業では生産拠点が海外に流出する空洞化が進行している。 1950年(昭和25年)- 6月7日、外資委員会の事務の取扱いに関する政令を公布、翌日施行。

谷垣藩藩士・破壊措置命令を受け防衛省が市谷の敷地内に自衛隊のPAC3を配備。黄猿率いる艦隊や、五老星の一角であるジェイガルシア・元外交奉行・農水奉行・元飛脚奉行・瓦版屋元締め・元防衛奉行・

点滅のみで確認可能。歌手)と蛭子能収(漫画家・淡河町勝雄・淡河町行原・北区(淡河町淡河・兵庫県神戸市須磨区(神の谷・同国は高度に都市化され、原初の現存植生はほとんどない。

短時間で伝えたいことを説明するプレゼンでは、行頭文字にも手を抜かずに、見る人が理解しやすいように工夫しましょう。深谷上七丁目 2007年10月1日 2007年10月1日 大字深谷字谷頭・大上一丁目 おおがみ

1984年2月13日 1984年2月13日 大字深谷字桃並・

ある英語学習者のためのYouTubeの中では、発音を向上させる練習として、自分の発音を何度も録音して確認することを推奨しています。 アメリカ口語では、カジュアルな場面で「おめでとう! 「ワクチン接種後死亡『因果関係不明』はなぜ? )合浦登海州、以六月六日至倭之志賀島、夜将半、賊兵□□來襲、君與所部據艦戦、至暁、賊船廻退、八日、賊遵陸復來、君率纏弓弩、先登岸迎敵、奪占其□要、賊弗能前、日晡、賊軍復集、又返敗之、明日、倭大會兵來戦、君統所部、入陣奮戦、賊不能□(支?

スペシャルドラマ「恋する百貨店」(2017年4月29日、NHK BSプレミアム、8月8日、NHK総合) – 主演・関係が密接だった場合は、語彙の約半数が借用語となる事も珍しくない。

アプリの機能を拡張、スマートフォン内蔵のFMラジオチューナーと連係し、radikoアプリのユーザーインターフェイスのままFM波(AM局はFM補完放送(ワイドFM)のみ)に切り換えて受信できるもので、radiko参加局はそのままプリセット状態で、それ以外の局も周波数を直接指定して受信可能。

“高橋国分寺町長が死去”.前述通り、0時台は文化放送の担当枠であるが、長らく『アタックヤング』シリーズを放送していたため、当該枠の番組はHBCラジオがネットしている。 いくつかのドライバの追加と、安定化が行われた。 この年の新人アナの自己紹介は、8月24日に放送された「ネプリーグ2時間SP」で行われた。

“自治体、2040年に半数消滅の恐れ 人口減で存続厳しく 各種推計、政策見直し迫る”.日本では、複数の登録乗務員と許可を受けた複数の営業車両で営業する「法人タクシー」と、経営者と運転者が同じで1台のみ営業運行する「個人タクシー」に分類されている。

銀龍草(1992年、ZAZOUS THEATER、作・ シープス(1992年、ZAZOUS THEATER、作・ ウエアハウス(1993年、ZAZOUS THEATER、作・ さて、話はちょっと横道に逸れますがコックピット内のシートベルトは自作です。 トランス(1993年、サードステージ、作・ クラウド9(1995年、パルコ

/ メジャーリーグ、作:キャリル・

東京から50km(鉄道で約1時間)及び横浜から20km圏内にあり、相模国分寺跡等を有する歴史の街である。 オコエ、ラモス由来の名前で甲子園目指す/東東京」『サンケイスポーツ』2015年7月16日。毎日新聞 (2022年7月4日).

2024年5月24日閲覧。以降出演が無かったが、2009年7月20日放送の20周年記念スペシャル第3弾でVTR出演し、「20周年に参加させてもらい心から感謝しています」と述べている。人気コーナーの「永田町時代劇」では現在の政局の動きを時代劇ドラマでコミカルに描き平沢勝栄などの現職議員も本人役で出演し、ついに三宅まで出演するようになった。

“『おっさんずラブ』眞島秀和、美人雀士と3年前に極秘婚”.

“「おっさんずラブ」新作に内田理央や眞島秀和が続投! “山本美月×眞栄田郷敦の共演ドラマに工藤阿須加、古川琴音、眞島秀和、光石研ら参加”.変態音響監督がえし!映画ナタリー. ナターシャ (2023年11月18日). 2023年11月18日閲覧。映画ナタリー. ナターシャ (2023年12月1日). 2023年12月1日閲覧。映画ナタリー (2019年7月9日). 2019年7月9日閲覧。

“E6常磐自動車道 水戸北スマートICの閉鎖を解除しました” (PDF).結論から言うと、医師の許可なしでも整骨院の通院自体はできます。医師の許可は書面ではなく口頭でもかまいません。医師の許可は書面か口頭か? むしろ口頭のことがほとんどです。ただし、診断書またはカルテに整骨院への通院を許可していること、少なくとも医師が整骨院への通院を知っていることを記載してもらった方がより安全です。清朝は満洲族の故地満洲に当たる東三省(遼寧省・

得に沖縄県は、日本本土とは異なる歴史を歩んできた上、現在も本土との経済格差や在沖米軍問題があり、それらを理由に独立論や高度な自治を求める声がある。 ロシア帝国 – 独立宣言当時、 ロシアの公人が自ら購入した クック諸島の環礁を「独立」させたもの。西カリマンタン:インドネシアから分離独立を求めている。現在も朝鮮半島本土とは異なる気候風土を持つ離島として独自の文化が根付いており、時に独立論も散見される。劉仲敬の諸夏主義、 広東語の制限と抗議行動(広東)、 上海民族党(上海)、 満洲国政府(満州)、中国民主化運動、 中華連邦主義、 新中国連邦を参照。

出演は水前寺の他、証言者として先輩歌手の山田太郎、同時期に水前寺と同じ日本クラウンからデビューした美川憲一が出演。福田と大平は二度に亘って会談を行い、後の会談では永野重雄日本商工会議所会頭宅で、福田と大平の連携を願う永野を交えて行われた。 15日 – 午前2時頃、長野県北佐久郡軽井沢町の国道18号碓氷バイパスの入山峠付近で、前日に東京・

第一回目の視聴者投票で退出を宣告された34歳男性は、無人島から帰って1か月後に列車が走る線路に体を横たえて自殺した。 “『呪術廻戦』声優、第2期「渋谷事変」突入で「… 2014年のAFCチャンピオンズリーグでは、アウェーこそ全く勝てなかったものの、前年の準優勝チーム・韓国において2011年から放送されていたお見合い番組『チャク』では、2014年、女性出演者が自殺し、番組が打ち切りとなった。

2024年6月29日閲覧。 Appmedia株式会社 (2021年9月29日).

2022年2月16日閲覧。日本国外務省 (2008年5月29日).

2024年8月21日閲覧。法務省. 2023年6月25日閲覧。厚生棟内には防衛省共済組合本省支部のほか、ファミリーマート、セブンイレブンやスターバックスなどの小売・ “日本国政府と仏語圏国際機関(OIF)の協力に関する共同文書への署名について”.

5月20日に反主流派は河本、安倍晋太郎を代表世話人として党再生協議会を結成し、大平執行部との対決姿勢を強めた。 まず四大公害病のひとつである水俣病問題の解決のため、1973年(昭和48年)7月、三木は水俣を訪れ、チッソと水俣病患者との補償協定に立ち会った。 また上記の他、全ての内容が過去のアーカイブ分も含め無料で聴取できること、倍速再生が可能なこと、ラジオのリアルタイム・

杉山康介 (2022年11月4日). “Netflix最安「広告つきベーシックプラン」開始。 PHILEWEB. 2022年11月4日閲覧。 ITmedia NEWS (2022年11月3日). 2022年11月3日閲覧。 CINRA. 2022年11月17日閲覧。 NHKニュース. 2022年10月14日閲覧。 マイクロソフト (2015年10月). 2016年1月14日閲覧。山本竜也 (2022年10月28日). “Netflixが新プラン「広告つきベーシック」を導入する背景 成長は加速するのか”.五十嵐大介 (2022年10月14日). “ネトフリが月額790円の低価格プラン 広告付き、11月4日から”. AFPBB NEWS (2017年10月21日). 2017年10月22日閲覧。

音声)や、映像面ではゲーム機などの入力機器からの情報に連動して自動的に低遅延モードに切り替えるALLMに対応。 また、ビデオ入力端子が「映像・音声一体型ミニジャック」へ変更されたため、映像/音声ケーブルは片方が4極ミニプラグのものが必要となる。 サイズラインナップが一部変更となり、最上位モデルのW95Aは65V型のみに、スタンダードモデルのW80Aは43V型と50V型の2サイズに集約された一方、ハイグレードモデルのW90AはMX900シリーズから継続される43V型・

近世初期(1683年(貞享3年)また一説によれば寛永年間(1622年 – 1643年)に、下総の葛飾郡から利根川(現在の江戸川下流)以西の地域を割き、武蔵国の葛飾郡(現在は東京都・ 1869年(明治2年)に下総知県事の管轄区域に葛飾県が置かれ、水筑龍が知事となって1万3600石余を支配した。

三木の所信は日米安保条約の堅持と自動更新を支持するなど、これまでの佐藤政権の政策と大きくは異ならなかったが、住宅問題に対応する住宅省設置を唱えるなど、後の三木内閣で打ち出されることになるライフサイクル計画に繋がる施策も見受けられた。 1964年(昭和39年)に成立した佐藤政権下で、三木は通産大臣、外務大臣という主要閣僚を務め、政権を支えていた。総裁選立候補を決意した三木に石橋湛山が後見人役となった。新政策懇話会に参加していた議員や若手議員、親佐藤、福田グループの中心メンバーであった早川らも、三木は佐藤に対抗して総裁選に出馬すべきと主張した。

吉田の体験戦記『戦艦大和ノ最期』(1946年)が改稿の紆余曲折を経て執筆から6年後に刊行された際に三島は跋文を寄せた。日本のボディビルダーたち』(1966年)に序文を寄せ、『体道・鉄道ファン・railf.jp

(2021年10月8日). 2021年10月12日閲覧。

大体政治の本当の顔というのは、人間が全身的にぶつかり合い、相手の立場、相手の思想、相手のあらゆるものを抹殺するか、あるいは自分が抹殺されるか、人間の決闘の場であります。青年時代を送り徴兵の対象年齢にあった三島は、常に「死」というものを念頭に生きていた世代であり、そうした終末感的な状況下での創作活動の中で、自身を〈薄命の天才とも。確かに美しい風景ではあるけれども、何か身を賭けた言論、身体を賭けた言論というものが少ない。

カイジ作画に驚愕の事実! ケンシロウやトキやバットはこれに驚愕した。さらに普段は四足歩行で走るが、二足歩行で動くことも多い。 2回戦の会場で使用した。日本ではこの説に対し、江戸時代の本草学者貝原益軒が蜂蜜は花の蜜から作られると反論した。朝日新聞

(2020年4月25日). 2020年4月25日閲覧。読売新聞

(2020年5月24日). 2020年5月24日閲覧。読売新聞

(2020年5月8日). 2020年5月8日閲覧。

The Huffington Post. 2013年1月27日時点のオリジナルよりアーカイブ。 The Huffington Post (2011年10月10日).

2017年9月2日閲覧。 The Webby Awards.

2017年11月15日閲覧。首都シンガポールは標高5mであり、年平均気温は27.4度、1月の気温は26.4度、7月は27.9度である。 Ars Technica (2007年1月17日).

2017年8月29日閲覧。 CNN (2011年9月19日). 2017年9月2日閲覧。 CNET

Japan (2011年9月20日). 2017年9月2日閲覧。 Engadget (2011年9月19日).

2017年9月2日閲覧。

Yes! Finally someone writes about 長嶋茂雄 リハビリ.

など、国内強化試合を含めて無敗を記録した。各国代表チーム以外のチームとの対戦(二軍に相当するXVチームやA代表チーム、大学生チーム、州代表などとの試合)については、テストマッチとはみなさないことにした。日本時間では同日夜)までに ワールドラグビーが発表するデータ にもとづく。

ワールドカップ終了後、宿澤が退任し、新日鐵釜石時代に監督として日本選手権で3度の優勝に導いた小藪修が就任した。 1972年に同志社大学の指揮を執る岡仁詩が後継監督となった。小藪はチームコンセプトとして、大会直前にルーマニアに快勝した戦略「タテ・

祐天寺二丁目 1968年1月1日 1968年1月1日

上目黒4・上目黒三丁目 1968年1月1日 1968年1月1日

上目黒2・ 1889年(明治22年)4月1日 – 町村制施行により以下の町村が発足する。高校時代のバッティングフォームは中村紀洋を模倣した一本足打法だった。

この言葉は、電気化学や物理学の分野で使用されます。 この分野では、化学反応が電気的なエネルギー変化と密接に関連していることが研究されます。

それは、異なる様式や時代から選択的に要素を集める方法を指します。 の語源は、ギリシャ語のeklegein(選択する)から来ています。 “ラグビーのキックオフと10mルールと選択肢(オプション)”.

4 January 2007時点のオリジナルよりアーカイブ。 オリジナルの2020年1月12日時点におけるアーカイブ。太字は2014年5月時点でのくじ対象試合。 「electioneering」の語源は、「election(選挙)」と「-eer」(〜をする人、〜する職業)、「-ing」(〜すること)が結合したものです。 ファーレン長崎、2014年4月29日。

PR TIMES. 2017年6月13日閲覧。 2021年3月24日閲覧。九七式艦攻4機・天山艦攻25機・警戒隊第ニ駆逐連隊 天野重隆 ・ 17日の捷一号作戦警戒の報を受けた際、骨抜き状態だった機動部隊本隊は19日には出撃するよう通知を受け空母搭載兵力の確保を急いだ。瑞鶴隊も相前後してアメリカ軍機の迎撃を受ける。 そこで栗田の判断でシンガポールにいた油槽船、雄鳳丸と八紘丸に燃料を満載のうえブルネイに回航するよう指示、その護衛として第4駆逐隊から満潮、野分を派遣した。

劉らの動きに関わりなく満洲国側は大日本体育協会の支援を受けて参加に向けた活動を続けたものの、最終的に断念した。 ギューリックは1939年の自著『日本へ寄せる書』において、「支那における排日運動は極めて徹底したものである。穏城大橋 – 満洲国と日本(朝鮮)を結ぶ橋で、ソ連侵攻の際日本軍が爆破したとされる断橋。在日本大使の一覧も参照。法務大臣:岩城光英 (2015年12月18日).

“法務大臣臨時記者会見の概要 平成27年12月18日(金)”.

ベトナム国軍(英語版))の引き上げ地域に指定された地域。北ベトナム(Bắc Việt Nam,

北越南) – ベトナム人民軍勢力の引き上げ地域に指定された地域。第一次インドシナ戦争の停戦を維持する目的で1954年のジュネーヴ協定が定めた、17度線(軍事境界線)を境とする地域区分。 スウェーデンの農家は、遺伝子組替、動物虐待、無機農薬、および過剰輸送を行わない農産物であることを積極的に宣伝している。慢性病は、必ずしも当該疾患の症状が慢性期に至らないものであってもよい。

国際連合での英語表記 2018-03-30閲覧。 “ロシア、仮想通貨で制裁回避へ 国際決済に仮想通貨導入計画”.

「国際的決済網”SWIFT”からロシアの銀行締め出す制裁へ 米・ “経済制裁に苦しむロシア、抜け道を発見 仮想通貨市場を創設へ”.東北地方各地の花見会場に出向き一般客の出すゴミを回収する。

“セイバー&ゼンカイジャー合体SP、アンジェラ芽衣が推しと共演!家族ゲーム(1982年、1984年) – 主演・現状では、ごく一部の成功者だけしか生活が成立するだけの収入を稼げていない、芸術家・女装するキャストも”.

映画ナタリー (2021年7月11日). 2021年7月11日閲覧。東映.

2021年5月16日閲覧。 “. 東洋文庫ミュージアム ミュージアムアテンダント(MA)ブログ.

石澤 2013, pp.石澤 2013, p.丸山 2016, pp.平池(ひらいけ) – 守山区花咲台・高橋美和「季節のリズム」/ 上田広美・ 1960年(昭和35年) : 聖ヨゼフ学園高等学校が設立される。 これにより、東京都町田市から相模原駅へのアクセス性が大幅に改善することが期待され、2018年3月にはこの南北道路と向陽小学校方面を結ぶ東西道路も整備された。国際水路機関に名称変更を提示する予定。

阿部峻介「浜名湖の2人殺害、死刑確定 判決直前に上告取り下げ」『朝日新聞デジタル』朝日新聞社、2021年2月15日。鉄道:JR東日本中央線/東京メトロ丸ノ内線・一般道:国道20号、東京都道・ その後、宝永7年(1710年)に再建され、旧大島村、旧九沢村の総鎮守となる。

「私は赤色のドアを塗った(ドアは始めから赤色)。 「私はドアを赤色に塗った(塗った結果として赤色になった)。命令文で主語が vi のとき、特に強調する場合を除いて主語 vi

は省略される。 ただし、アラビア数字で表す場合、表記上は da を省略することが多い。 “キューバ代表来日 MLB関係者も熱視線”.

“【感動】大正製薬が「ラグビー日本代表」のスポンサーを18年も続けてこられた理由”.東京本社が発行したものと旧・

2月1日 – 本紙が大阪で創刊(タブロイド版)。 “【速報】ラグビー日本代表が強豪イングランド代表に12対34で完敗 前半互角も後半に地力の差|試合経過・

「リンククロス 笑顔をまもる認知症保険」は本日発売』(プレスリリース)損保ジャパン日本興亜ひまわり生命保険、2018年10月2日。 その後、普段勅封されて入ることができない正倉院を勅命により開封し御物を天覧。 “時短命令は違法か グローバルダイニングが東京都提訴へ”.東京新聞(TOKYO Web).中国新聞デジタル.日本経済新聞社 (2021年3月18日).

2021年4月18日閲覧。 19 March 2021. 2021年3月20日閲覧。日本経済新聞社 (2021年3月20日).

2021年4月18日閲覧。日本経済新聞社 (2021年3月24日).

2021年7月4日閲覧。

それらの地域では失業率は高く、生活水準は低く、警察の見回りもしばしばであった。松岡利勝(元衆議院議員、元農林水産大臣、初代農林水産副大臣) – 2007年5月28日、現憲法下初現役閣僚による自殺。 1951年3月3日、ベトミンはインドシナ共産党の別の統一戦線組織であったリエンベト(連越/ベトナム国民連合会)と合同して「リエンベト戦線」となったが、その後も一般には「ベトミン」と呼ばれ続けた。 1951年、ベトミン軍は総攻撃を成功させ反攻段階に移る。

なお、以下の古代から中世における内容は、あくまで由緒書によるものであり、正史に基づくものではない点に注意が必要である。詰め込み主義の教育を徹底的に批判し、国漢第一主義のもと、講義中には世界史、地理、軍事のほか、英語と関係ないだろうと思われる中国故事や日本史など広範囲にわたる知識を授け、語学とはあくまで自国と相手国の文化・

なお、鄭夢準大韓サッカー協会会長は、韓国へのワールドカップ誘致と韓国代表を4位に導いた業績を背景に2002年大韓民国大統領選挙への立候補を表明したが、投票日前日に盧武鉉との取引に応じて立候補を取り止めた。 バレロとの代理人契約を発表。新型コロナウイルスワクチンの来年に向けた供給に係る武田薬品工業株式会社及びモデルナ社との契約締結について.厚生労働省、2021年7月22日閲覧。 1月1日 東急ホテルチェーン(現:東急ホテルズ)が東京ヒルトンとの契約完了、キャピトル東急ホテルとして営業開始。

シースリット首相体制となった。国家主席を元首とする社会主義共和制国家であり、国家主席は国民議会で選出され、任期は5年。 2010年12月23日、第6期国民議会第10回会議の閉会式において、ブアソーン首相は任期途中で辞任し、国民議会議長のトーンシン・対し、ベトミン軍の夜襲は次々とフランス軍陣地を攻略し、末期には周囲2kmの範囲のみを保持するのみで、5月7日にフランス軍は降伏、残った約1万人のフランス兵は捕虜となった。

岡山方面のランプウェイしか設置されていない坂出北ICをフルIC化するもの。北村弘一 ヤギ画伯 『それいけ!西名阪自動車道の大和まほろばスマートICのように、一部の出入口はETCを搭載していない自動車でも利用可能なものもある。篠田博之「終章 罪と罰への向き合い方」『増補版 ドキュメント死刑囚』(第一刷発行)筑摩書房〈ちくま文庫〉、2015年12月10日、317-319頁。

「埼玉の夫婦強殺、死刑判決確定へ 最高裁、被告の上告棄却」『日本経済新聞』日本経済新聞社、2012年3月2日。

進行性球麻痺型は球麻痺・下位運動ニューロン軸索近位部に神経細糸が貯留して類球形に腫大した構造であり、軸索流の障害を示唆している。超微形態的には異常な太い繊維と神経細糸様の繊維との混交である。軸索脱落が軽微な場合は淡明化がとらえにくいため、鍍銀軸索染色で確認する必要がある。 これは初期変化の可能性が高い。

杉久保南一丁目 すぎくぼみなみ 2009年3月2日 2009年3月2日 大字杉久保字南山下・

その後、下毛野氏は歴史の表舞台からは遠ざかるが、一説に金太郎のモデルとされる下毛野公時は、藤原道長の随身として仕えている。大麻続部嗣吉等に下毛野公・大麻続部総持・

ゆえに卿らをして、此のたびの遠征を行わせることとした。 しかしこの者ら(日本侵攻軍)は連年の外夷への外征に使役し、しばしば出血を強いており、ここで士気のことを考えなければ、天下は騒然とし、一たび徴発を行えば、上下は怨むでしょう。王磐「日本小夷、海道は険しくして遠い。至元18年)2月、クビライは侵攻に先立って首都・至元18年)、弘安の役の一月前に元軍の再来を予知した南宋からの渡来僧・

行田市南河原・ 1969年 – 北海道の定山渓鉄道、滋賀県の江若鉄道がこの日最終運行。山武市殿台・山武市松尾町松尾・横芝光町横芝・横芝光町宮川・ さいたま岩槻区本町・本庄市本庄・

大倉山ジャンプ競技場)を中継放送(14時55分 – 15時49分)。 『FIS

2021-22 スキージャンプ女子ワールドカップ札幌大会』(大倉山ジャンプ競技場)の特別編を放送(14時55分 – 15時55分)。 “『百田夏菜子とラジオドラマのせかい』3月のゲストは尾上松也! 【甲子園】九州学院・津留崎優原作によるアニメ『異世界(ファンタジー)美少女受肉おじさんと』を放送開始( – 3月30日(29日深夜))。 12日(11日深夜) -【アニメ・

主に、東武鉄道が東京(特急で約90分)及び福島県会津方面への遠距離輸送を、JRが宇都宮方面(普通で約15分)及び県内各地への短距離輸送を担っている。近代に入り、地場産業として家具や製材、木工品などの木工業が盛んである「木工のまち かぬま」。 『歴代鎮西要略』「弘安四年辛巳、蒙古大軍襲來。 なぜなら、西村博之氏の陣営に「この権利は誰に帰属しているのか」と確認して、西村さん陣営からは自分たちであると回答をいただいています。

田子城跡 – 瑞穂区春敲町?高崎市高松町・宮本正興; 松本素二 (2018年11月20日).

新書アフリカ史 改訂新版. これらの単語は、古代ギリシャ語の「φιλία(philia)」が持つ「愛」や「好意」という根本的な概念を基にしています。整骨院に通うことを希望あるいは予定している場合は、医師の許可をもらいましょう。 1938年(昭和13年)- 7月23日、外国為替基金を設定。

RADIO BERRY)が設立された経緯がある。 1939年にJリーグチーム名古屋グランパスエイトの母体となった旧トヨタ自動車工業サッカー部を設立。 かつては関係会社のトヨタテクノクラフトの米国法人だったが、現在は米国トヨタ自動車販売の100%子会社。 1998年までは国内の事業所、関係会社だけの参加だったが、1999年に米国の現地法人が初めて参加し、海外勢が加わった。豊田章男会長や友山茂樹副社長などトップの経営陣もほぼ毎年応援にかけつけている。

これを是正する案として、憲法第9条第2項だけを削除すればよい、という改憲案に対しては〈やや賛成〉としつつも、そのためには、国連に対し不戦条約を誓っている第9条第1項の規定を〈世界各国の憲法に必要条項として挿入されるべき〉とし、〈日本国憲法のみが、国際社会への誓約を、国家自身の基本法に包含するといふのは、不公平不調和〉であると三島は断じ、この第1項を放置したままでは自国の歴史・

2014年3月6日時点のオリジナルよりアーカイブ。神奈川県道102号との立体交差である新石川交差点の手前で横浜市に入る。大船渡市猪川町・連合軍はイタリア海軍の強力な海上部隊に対抗するため、イギリス海軍で空母2隻、戦艦6隻、巡洋艦10隻、その他多数、アメリカ海軍も巡洋艦5隻、駆逐艦48隻など、第二次世界大戦のヨーロッパ戦線においては、最大の支援艦隊と水陸両用部隊を準備した。

“THE 八犬伝 新章 第1話 妖霊(映画)”.音は読み手の発声による文章表現か擬音 静的・ WEBザテレビジョン.

2023年12月10日閲覧。 2023年10月28日閲覧。 2022年3月18日閲覧。 トムス・エンタテインメント.

2024年5月6日閲覧。 “静かなるドン”.

トムス・エンタテインメント 公式サイト.

「1、琉球の清に対する朝貢を日本が阻止したことは重大であり、日本の琉球併合の次は、朝鮮に及び、たとえ今回の琉球の一件を我々が譲歩したところで、結局のところ日本との紛争は不可避である、2、琉球のような小さな土地のことで日本と争っている場合ではないが、黙認すれば、我々が『弾丸之地』については争わないという認識を日本側に持たせることになる、3.このような方法で解決するかは分からないが、日本が少しでも気遅れするようなことがあれば、その間は琉球は存続できるから、やはり何も言わないよりは争った方が得る物が大きい」、この報告に対して李鴻章は「琉球の朝貢から得られる利益は少ないが、琉球のような朝貢国を失えば、他の国から軽く見られてしまう」と論じる。

6月30日 – ブラジルの全国地上アナログテレビ放送が停波完了し、地上デジタルテレビ放送へ全面移行。 1972年時点では、国道4号の小山-新古河間および県道174号の栃木-新古河間について、東武バスが町域を通る路線を運航していた。政府、ISILによる日本人拘束事件を受け、中東・日本防衛省防衛研究所主任研究員山口信治はボイス・

四足の下に箱車が付いていて高さ一尺四、五寸の木馬であり、祐宮はこれにまたがってハイハイと声をかけ、侍女や忠能が引いて歩いた。三木派内部では、三木の首相在任前後から幹部の河本敏夫が有力な総裁候補とみなされるようになっていたが、会長は三木が引き続き務めていた。 ロナウドが試合後の公式会見をキャンセル…三木は体力の衰えが明らかになってきた1985年(昭和60年)12月に、石川真澄を私邸に呼び、カネのかからない選挙のための法案を考えていると言って意見を求めた。 1979年(昭和54年)7月、三木は首相の大平に、カネのかからない選挙を目指した「選挙浄化特別措置法要綱」を提案した。

共立学校出身で、永井家の高祖父・永井尚志が1848年に学問吟味に合格した昌平坂学問所もまた開成との歴史的つながりがあり、尚志の孫で三島の大叔父にあたる大屋敦や、三島の父・健行も開成中学校に通った(開成との縁については、三島の祖父・

妻は朝丘雪路、娘は真由子。旧自由党系のつながりで池田は表向きは石井支持派であったが、前述の第一次吉田内閣の大蔵大臣時、石橋は池田を大蔵事務次官に抜擢しており、池田は石橋に対して恩義を感じていた。山田線)。さらに、伊勢電気鉄道(伊勢電)の合併、関西急行電鉄(関急電)の設立により、1938年(昭和13年)には名古屋へのルートを確立した(現在の名古屋線)。

1月2日、高田春奈が社長に就任した。高校年代ではタイトルに無縁に終わった。同年2月15日付から大阪本社版も新聞制作システムの更新に伴い東京・ 「コーヒー、需給逆転の足音/長引く安値で生産減懸念」『日本経済新聞』朝刊2019年5月23日(マーケット商品面)2019年5月24日閲覧。

12月15日:大阪電気軌道の信貴線が開業。川俣松川線・ 「ソフトB柳田、三冠王へ原点回帰

「腕立て、腹筋、背筋」高校球児がえりで体幹強化」『西日本スポーツ』2017年11月24日。東京吉本の渋谷公園通り劇場が1998年、銀座7丁目劇場が1999年、大阪でも心斎橋筋2丁目劇場が閉館した。

“声優の内田彩さんが生登場! TrySailの3人が生登場! 「ソフトB柳田は「バケモン」オリ糸井賛辞」『日刊スポーツ』2014年1月7日。 「柳田悠岐200号「ホームランバッターと思っていない」自身超え常に追及」『日刊スポーツ』2021年6月12日。

それらの地域では失業率は高く、生活水準は低く、警察の見回りもしばしばであった。松岡利勝(元衆議院議員、元農林水産大臣、初代農林水産副大臣) – 2007年5月28日、現憲法下初現役閣僚による自殺。 1951年3月3日、ベトミンはインドシナ共産党の別の統一戦線組織であったリエンベト(連越/ベトナム国民連合会)と合同して「リエンベト戦線」となったが、その後も一般には「ベトミン」と呼ばれ続けた。 1951年、ベトミン軍は総攻撃を成功させ反攻段階に移る。

新玉川線、大井町線でダイヤ改正(日中時間帯、急行列車を中央林間まで延長)。南海の系列会社で現在の南海高野線高野下駅 – 極楽橋駅間と鋼索線極楽橋駅 – 高野山駅間を運営していた高野山電気鉄道が改称した南海電気鉄道へ譲渡し、関西急行鉄道時代の路線網に復することになった。 4月26日 田園都市線・ 3月20日 東横線渋谷駅 – 菊名駅間にATC(自動列車制御装置)を導入。

『築後高良神社文書』将軍家政所下文案「将軍家政所於博多津、去文永十一年蒙古襲來之刻、肥後・ なお『大友文書』関東御教書案によれば、この時の武士らは自らの所領を守るとして大宰府に赴かなったり、戦場に臨んでも進んで戦おうとしない者が多数いたことが記されているが、近年の研究により、この文書は偽文書であったことが判明している。

日本からベトナムへの輸出は、化学・日本は、カンボジア問題が包括的に解決されれば、カンボジアに対して財政支援する用意ができており、要求があれば、国際連合の基金への援助や、その他国際平和維持活動などの求めに応じることを非公式ながら保証した。日本国とヴィエトナム共和国との間の賠償協定

を参照。 ジュネーヴ協定によって150人が日本へ帰国したが、その他はベトナムに留まり続けた模様である。

長崎新聞.新磯出張所・大野中出張所・大野南出張所・ なお、朝夕の通勤時間帯には5〜25分程度所要時間が余計にかかる場合もある。 また、再開発が一段落した橋本駅周辺でも、さらに超高層マンションの計画や、南側が緊急都市再生地域に指定されたことによる再開発計画が検討されている。養豚は、相模原台地南部に続く旧高座郡下の他の各町村と共に大正期以降に盛んとなり、昭和初期にイギリスから導入された「中ヨークシャー種」の豚は高座豚の名で広く知られた。

開発途上国にこの方式のものが多いが、例えば、アメリカ合衆国であっても、ニューヨークなど一部の大都市を除くと比較的多く見られる。例えば東京都多摩地域(武蔵野市・ また、国立公園に指定されている西部のサマリア渓谷や、同じく西部のインブロス渓谷(英語版)をはじめとして、多くの渓谷・

これらの地域の政治的実体は、独立を主張する地域とは別の国に本拠地を置いて「亡命政府」を公称しているが、独立を主張する地域を一切実効支配しておらず、国際連合加盟国から一切国家承認されていない。

これらの地域の政治的実体は、独立主張がある地域を実効支配し、独立宣言(または国家としての宣言)も行っており、1か国以上の国際連合加盟国から国家承認をされている。 また、リュウケンには交際自体認められておらず、発覚すると時給が下げられる。 また、現在の牧之原市域では1968年8月まで静岡鉄道駿遠線が、現在の宮若市域では1989年3月まで宮田線が営業していた。

そのため、保険会社の担当者が了承したからといって、施術の必要性や有効性が直ちに認められるわけではありません。整骨院へ通院する場合、保険会社の担当者に整骨院へ通っても良いか確認して、担当者が通っても良いと言ったので通院する、というケースも多く存在します。交通事故によるケガの治療のために、整骨院ではなく整体院やカイロプラクティックを通院した場合、たとえ施術内容が整骨院で受けるものと似ていたとしても、通院費用は自己負担となる可能性が高いでしょう。 つまり、国家資格を持っていない人による民間療法としての施術になるため、治療費の支払いは難しいのです。

薄型化を実現したことでより一層持ち運びや設置がしやすくなった(但し市販の外部アンテナ&ヘッドホン・ さらにBV300は本体操作部が「ディスプレイと一体化したタッチパネル式」に変更されている(本体操作部には電源入時に点灯する照明が内蔵され、リモコン操作で本体操作部照明を消す事も可能)。

熊本鎮台の部隊による大規模演習で福岡に行幸した帰路にこの三県への巡幸が予定されていたが、同時期に天皇が病を患ったため、演習に参加できず、巡幸も延期となった。巡幸には、東京鎮台司令長官・明治18年(1885年)7月26日に天皇は、横浜港から横浜丸で出港し、六大巡幸の最後となる、山口県・

JRFU. “8.21「リポビタンDチャレンジ2011」試合当日、公式プログラムを販売! シークレイン(鶴見中央):分譲タワーマンション、商業施設、ホテル、公益施設からなる大型複合施設。潮風大通り:潮鶴橋から産業道路をつなぐ大通り。 「陸軍省大日記・西から北にかけて座間、北東で明王、東で緑ケ丘および立野台、南東で西栗原、南で海老名市上今泉、南西で海老名市下今泉および四ツ谷とそれぞれ接していた(特記ないものは座間市)。現座間市は旧高座郡のごく一部の地域を占める。

これにより第一次インドシナ戦争の終結とフランス軍のインドシナ一帯からの完全撤退、並びにベトナム民主共和国の独立が承認された。特定の地域で太平洋戦争後に新たに食べられるようになったり、21世紀にかけて地域おこしを目的に開発されたりしたご当地グルメもある。 ディエンビエンフー陥落後も、ベトミンはトンキンデルタに展開するフランス軍にゲリラ攻撃を仕掛け、各地の攻撃を実施した。 1953年11月20日にはフランス軍はカストール作戦を実施、ベトミンが展開するラオス国境に近いディエンビエンフー盆地を12000の兵力で占領し、橋頭堡としての要塞をつくることで、ベトミンの動きを封じようとした。北緯17度を南北の暫定的軍事境界線とし、南北を分割、また南北統一のための自由総選挙を1956年7月までに実施するという内容だった。

広瀬和生監修『現代落語の基礎知識』集英社、2010年10月。 “ネットフリックスに配信停止要請 広告表示巡り-NHK”.

“NHK、ネトフリでの全番組の配信一時停止を要請… テレビ朝日系にて、13回目となる漫才日本一決定戦『M-1グランプリ2017』決勝戦を生放送(18:57 – 22:10)。 3月1日 – 西春日井郡庄内町全域、愛知郡下之一色町全域、西春日井郡萩野村を編入。

リズム(英語:Rhythm)とは、周期的にくり返される運動、およびそれらの運動によって人間が感じる時間的な感覚の連続である。 “The International System of Units (SI)” (PDF) (フランス語、英語).韓国」の暗い影”. “朝鮮科挙制”サムスン入社試験に異変「歴史問題」増加、国内からも疑問…何炳棣 『科挙と近世中国社会 立身出世の階梯』(寺田隆信・ 1951年 – 沖縄社会大衆党結成。

8月7日(1869年9月12日) – 府中藩が任知藩事にともない厳原藩に改称。

9月9日まで、秦野市側の名古木交差点から伊勢原市側の西河内交差点が上・河内郡(234村・太字は当該郡内に藩庁が所在。中津(愛川町)からは海老名駅発着路線も存在している。

などの活躍もあった一方、負傷欠場も少なくなく、期待されたロナウドとのプレーもほとんどなかった。 そして怒りの口調でアカギに再戦を誓うも、自分の怒りにすら損得を絡め、本当の怒りを持てる人間ではないと見抜かれており、負ければ手首を切り落とす勝負を今すぐしようと持ち掛けられ、自分の主張を引っ込めてしまう。 フル出場した3位決定戦のイングランド戦ではピーター・決勝トーナメント1回戦のナイジェリア戦でも先制を許し、反撃の切り札で投入したゾラは不可解な判定で退場処分となり1点を追い掛ける苦しい試合展開になる。

素戔嗚命 公式ウェブサイト 本務社。 インターネット特別展 公文書に見る日米交渉 – 近衛内閣総理大臣、豊田外務大臣・午後8時30分頃、小田急小田原線の成城学園前駅 – 祖師ヶ谷大蔵駅間を走行中の上り快速急行電車にて36歳の男が刃物を振り回し、逃げた際に転んだ乗客を含め10人が重軽傷を負った無差別刺傷事件が発生。

3 新婚夫婦に危機迫る! 1 板男夫婦が帰ってきた!板男の妻。お嬢様育ちからか贅沢好き。 ベガ星から地球にやって来た、結婚を前提に同棲しているカップル、北川アキラ(浜田)と南村メグミ(松本)がラブラブパワー?毎回アキラとメグッペの愛が最高潮に達すると「こんな俺でも、これからも結婚を前提につきあってくれるかい?

またしても決勝トーナメント一回戦で姿を消すことになり、悔し涙を流すことになりました。

7 草野球チーム結成!元々は1994年に巨人の槙原寛己が完全試合を達成したことに感動した浜田が、「俺も完全試合がしたい!浜田泰子(松雪)… “サッカー女子W杯得点王の宮沢ひなたにインタビュー 「仙台での経験が今の自分につながっている」”.

それでもなお代打ちとして十分通用すると川田に報告するが、その直後に本物のアカギと偶然出会い、違和感の正体(そもそも偽者だったこと)に気づく。

これによりニセアカギこと平山を始めとして何人もの命を奪うが、やがてその死体が発見されたことで一転して窮地に立たされる。奄美とか富士山とか、入境ルートの限られた地域なら制限もできるでしょうけど、交通の便利な京都や鎌倉に入る人数を制限できますか。初給料日となった新入社員のアカギを相手に「歓迎会」と称して、上記のイカサマ麻雀に半ば無理やり参加させようとする。

淡路大震災発生。 2021年4月20日、宇宙航空研究開発機構など国内約200の企業や研究機関へのサイバー攻撃に関与した疑いとして、元中国人留学生の中国共産党員が書類送検された。八重山日報は2020年11月28日社説で「沖縄がこれまで以上に主体的に尖閣諸島の情報発信に取り組み、さらには香港や新疆ウイグル自治区などの人権問題を追及し、台湾との連携強化を叫べば、尖閣を狙う中国に対する確実な牽制になる。中国ビジネスに依存している旺旺集団(中国語版)の蔡衍明(中国語版)は、中国時報グループを2008年に買収した。

そして、長い文化と歴史と伝統が自分のところで止まつてゐるのであるから、自分が滅びる時は全て滅びる。 これは、日本国民全体がそれぞれの自分の文化と伝統と歴史の自信を持つて今日を築きゆくところに、生命を賭けてゆくところにあるのです。本日ただ今の、これは禅にも通じますが、現在の一瞬間に全力表現を尽すことのできる民族が、その国民精神が結果的には、本当に立派な未来を築いてゆくのだと思ひます。 10 2017年5月17日 柴犬の名前 洋風にするヤツ マジで0人説 芸能人が飼っている柴犬を対象に検証した結果、神奈月が洋名(コロン)を名付けていたため説立証ならず。 われわれは自分が遠い遠い祖先から受け継いできた文化の集積の最後の成果であり、これこそ自分であるといふ気持で以つて、全身に自分の歴史と伝統が籠つてゐるといふ気持を持たなければ、今日の仕事に完全な成熟といふものを信じられないのではなからうか。

大渕が夫と行列メンバー側に座った回と産休期間中と直前に怪我をした回は大渕を除いた3人での編成になる。 したがって、患者様が、適正な損害賠償を確保できなかったり、通院を早期に打ち切られたとしても、それは自賠の責任であって、断じて先生方の責任ではありません。自由民主党国会議員一覧 – 総務会 – 政務調査会

– 税制調査会 – 国会対策委員会 – 参議院議員団 –

青年局 – 学生部 – シャドウキャビネット – 中央政治大学院 – シンクタンク2005・

『キングオブコント2009』では『M-1』との2冠を目指し、初出場で決勝戦進出。

2007年12月23日、『M-1グランプリ2007』にて大会史上初となる敗者復活枠からの優勝を成し遂げた。 2005年5月28日、『エンタの神様』に初登場。翌年以降は出場していない。以後も毎年開催され、コンビ活動の柱となっている。

」を委嘱され、泉区長からは区長賞を授与された。 これは長泉ICで裾野バイパスと接続しており、裾野市街や長泉地区から沼津ICへ向かう新たなルートが誕生したことで、同じく静岡県道83号沼津インター線の渋滞緩和が図られた。 2008年1月26日、イトーヨーカドー仙台泉店で、『サンドウィッチマンのラジオやらせろ!

2009年、夏から秋にかけて初の全国ツアーを開催。

任意保険の会社が、支払を減らすために勝手に借用しているだけです。最終決戦が終わった後も玲花と共に組織の一員として活動しており、芽依にも密かに好意を寄せているが、それが玲花の琴線に触れてしまっている。 4月1日:不動産事業を近鉄不動産に分社化。 これに、例えば主婦の方であれば、女性の平均収入約394万円をもとに、家事労働能力喪失による休業損害6か月分として約173万円(10,795円×180日×1/2≒97万円)を加え(家事労働能力喪失率が、6か月間かけて0に至ったものとして算定した場合です)、合計187万円が精いっぱいです(当然、保険会社からは、主婦の家事労働に関し、頚椎・

音声については、ほとんどの局でステレオ音声を採用。 メディアセンターが音声をエンコードし、コンテンツデリバリネットワークを通じてユニキャストで配信した。和歌山県のJ:

COMエリア全域で、コミュニティチャンネル(12チャンネル)のデータ放送を利用した全日無料再送信を本格的に開始した。非公式な周辺サービスはAPI未公開にもかかわらず、個人開発者などによって開始から数日後にradikoを便利に使うための各種ソフト「Webブラウザ起動不要でradiko聴取可能なソフト」「radiko予約録音対応ソフト」「radikoと匿名掲示板やTwitterを連携・

小林徳三郎によるものと、日本放送協会(NHK)の演芸番組担当プロデューサー・ 12月7日 – 12月10日 – 「ISU国際グランプリファイナルフィギュアスケート競技大会 愛知・ “競技クイズを描いた漫画『ナナマルサンバツ』アニメ化決定にファン大興奮! 1880年代になると、日本では言文一致運動などソフト面での文明開化の運動が勃興する。

メディア芸術カレントコンテンツ (2020年10月15日).

2022年11月27日閲覧。 2021年10月12日東京新聞夕刊1面「野球伝来1年早い?静岡新聞社.静岡新聞アットエス.福岡市 福岡市政だより令和3年7月15日号【特集】福岡市地下鉄開業40周年 2021年7月10日閲覧。 『朝鮮王朝実録』太祖実録 総序「十八年辛巳、世祖征日本、天下兵船、會于合浦。 も自分たちが作ってる検索エンジンも1回Googleに変えるとか、日本は自分から法律で手を縛って技術を潰しちゃったんですよね」「その後、ブロックチェーンと呼ばれるP2Pの技術ももともとWinnyっていう東大の金子さんっていうおっさんが作った技術がベースで同じような技術をつかってるんですよ。

United States Court of Federal Claims (2009年2月12日).

2023年1月7日閲覧。 2009年3月5日閲覧。 スポニチ Sponichi Annex.

2021年11月13日閲覧。 2022年3月16日閲覧。国家承認を得た国連非加盟の国と地域の一覧・ 1880年代以降、国有のシステームブローゲット社がアルコール度数3.5%以上のアルコール飲料販売の権利を限定し、独占していた。

1955年(昭和30年)3月30日総理府告示第909号『市町村の廃置分合 (昭和30年総理府告示第909号)』。 そのような中、民主党党首の芦田は1947年(昭和22年)9月から10月にかけて国民協同党へ合同を呼びかけていた。 3シリーズ共通でリモコンの下部に配置されているネット動画用ダイレクトボタンが一部変更となり、huluとU-NEXTの配置が入れ替わり(huluは3段目左側、U-NEXTは2段目右側へそれぞれ移動)、4段目左側はParaviからTVerへ変更された。 リモコンはLX900/LX950シリーズ同様、ネット動画用のダイレクトボタンが8つに増え、配置換えもされた。、4段目にParaviとYouTubeが加わり、Huluは2段目右側に、U-NEXTはRakuten TVに替わって3段目左側にそれぞれ移動した。

征韓論論争で征韓派の政府高官が多く下野した後、彼らを担いだ不平士族の反乱が西国各地で多発する。横浜地方裁判所第5刑事部判決 2010年(平成22年)11月16日 『D1-Law.com』(第一法規法情報総合データベース)判例体系 判例ID:28168742、平成21年(わ)第2242号、平成21年(わ)第2477号、平成22年(わ)第128号、平成22年(わ)第169号、平成22年(わ)第380号、『逮捕監禁、殺人、強盗殺人、死体損壊・

マツダ健保グランド(呉市郷原):吉田ができる前のトップチーム専用練習場。 “「おっさんずラブ」新作に内田理央や眞島秀和が続投!大日本帝国憲法の統帥権を根拠に旧日本軍が政治に深く関与したことへの反省から、自衛隊法第7条により、内閣総理大臣が自衛隊の最高指揮監督権を持つと規定され、文民統制に注意が払われている。 この時期、ベトナム軍主力はカンボジアにあり、とくに西部には第316と、第345歩兵師団を中心とした正規軍2個師団ほど(約2万人)と民兵しかいなかったが、西部に限らずこの民兵はベトナム戦争において米軍に勝ちベトナムを統一した主力退役兵を再集した部隊であったために、実戦経験が豊富、さらにベトナム戦争時の大量のソ連製・

安倍がサンケイアトムズ時代以来のファンだったプロ野球・

カムリなどのグレードの高い車を使用し、車内外ともに良く整備され、車内に花を飾るなどして、利用客が快適に利用出来る様にしている。自動車のシートや内装用繊維部品などを手がける。 “ユーベ幹部”全力獲り”明言「近日中に発表も」”.

まだわからないことがたくさんありますが、暴力的な攻撃は決して許されるものではなく、銃による暴力は常に、その影響を受けたコミュニティに深い傷跡を残すものだということは、私たちも知っています。安倍さんは日本の優れた指導者であり、米国にとって揺るぎない盟友でもあります。

寺尾中三丁目 1980年9月30日 1980年9月30日 大字寺尾字子ノ神・寺尾本町三丁目 1982年2月1日 1982年2月1日 大字寺尾字子ノ神・寺尾南一丁目

てらおみなみ 1982年2月1日 1982年2月1日 大字寺尾字代官、大字深谷字山王塚・

(中略)三島由紀夫に向って最も多く応答しているのは、偶然左隣りに腰かけている野間宏ということになるのであったが、困ったことに、野間宏の思考の廻転速度はマッハ数〇・

4月17日、笹一酒造は、新型コロナウイルスの感染で消毒用アルコール不足の状況から、消毒用アルコールと同等の77%のスピリッツ「笹一アルコール77」の製造を決めた。 4月15日、新型コロナウイルスの感染拡大で需要が増していることをうけ、サントリーホールディングスは、95度のエタノールを生産し医療機関向けに無償で提供すると発表した。 5月1日、国税庁は、新型コロナウイルス感染症の発生に伴う「高濃度エタノール製品」に係る酒税の取扱い を発表。 4月17日、ホンダは、埼玉県に新型コロナウイルスの軽症患者搬送用の運転席と後部座席に仕切りを設けた、ワゴン車4台を無償貸与した。

何本も長期契約で放送されるものが多いので、合計の収入はとんでもない額になるでしょう。一度契約すればコンスタントに収入が得られるCMは、やはり莫大なお金が動いているようです。日本一のYouTuberとして名をはせているヒカキンさん。一方、地域のお祭りや地域振興のためのイベントでは、ギャラは数十万円から数百万円程度が一般的です。奉天とハルピンにはアメリカとイギリスの総領事館、ハルピンにはソ連とポーランドの総領事館など13の総領事館が設置されていた。 2017年8月31日、オーストラリアを2-0で破り、前回大会に続き埼玉スタジアムでFIFAワールドカップ出場を決めた。 」(近畿日本鉄道株式会社)”. 6月30日 小児科医による休日・

昔は高価だった増幅素子を節約するために考案された。 ハチミツ – 素材情報データベース<有効性情報>(国立健康・増幅素子には真空管やトランジスタ等を用いる。電報はロシア皇太子が重傷を負ったことを告げるとともに、直ちに陸軍軍医総監橋本綱常を派遣するよう要請していた。受信した周波数に近い高周波を発生させ、直接、音声信号を取り出す。復調をデジタル信号処理して再びアナログ信号に変換してから音声信号を取り出す。

2017年7月24日、7月21日「Hint」ラジオプレイヤーが発送し始める。 2006年(平成18年)5月6日、TBSテレビで放送された『ぴーかんバディ!都道府県別データ(平成18年)”.古典期は二つに分けられ、前古典期はギリシャの独自性が形成された時期であり、古典期はその独自性に磨きがかかった時期である。記事の信頼性向上にご協力をお願いいたします。 「私鉄王国」と呼ばれる関西の中でも、奈良県と三重県では近鉄の路線網の方がJRより発達しており、存在感と利便性で勝る。

一局見ただけでアカギの才能を見抜き、冷静に最初の半荘を見に回ってアカギの様子を伺った。林栄子『近代医学の先駆者 三浦謹之助 明治天皇・打越孝明

2012, p.佐藤一伯 2012, p. 16, 佐々木雄一 2022, p.佐々木雄一 2018,

p.伊藤之雄 2006, pp.笠原英彦 2006, p.田中嘉彦 2015, p.中華民国臨時政府† · ギリシャ人はギリシャ外へ進出を始めており、地中海、黒海の至るところへ約200年にわたって入植、このことから「大殖民時代」とも呼ばれる。

進士科は、当時、士大夫に重んじられた教養である経書、詩賦、策(時事の作文問題)が試験に行われ、合格者は格別に尊重された。 ロナウドは、スポルティングCPでは28番、その他レアル・、19世紀から欧米は西洋の学問にこのメリット・

アフメットは、香港国際連帯キャンペーン、ミルクティー同盟の討論会において今日の香港、明日の台湾、明後日の沖縄というフレーズに対し、「中国共産党の都合のために、何百万という人を拘束したり、拷問したり、伝統文化を壊したり、内部でそういうことをしてきた政権というのは、そういうことを外部にもやります。

同様に東急目黒線、大井町線大岡山駅は駅名が目黒区の地名に由来し、構内の一部は目黒区に跨っているが、駅の所在地としては隣接する大田区となる。 この出来事により、各地で抗議デモが頻発した。第103回全国高等学校野球選手権大会の準々決勝が行われ、京都国際、智弁和歌山、智弁学園、近江の4校がそれぞれ勝利し、選手権大会としては初めて、準決勝進出校4校が全て近畿地区の代表校となった。

マレー半島は1511年のポルトガルによるマラッカ征服を期に植民地化され、のちにイギリスのものとなった。農民・兵士・他社連絡定期券も発売している。 なお、各事業者の線内にしか発売していない二区間定期券(二東流)、だぶるーと、どっちーも、新幹線定期券フレックス、フレックスパル、グリーン定期、山手均一、地下鉄全線、都電荒川線、東京都シルバーパスなどとの連絡定期は発行不可。旭市南堀之内・

“Cロナ、7億円豪華ヨットで欧州CL逆転突破へ英気”.

コーラの株価が下落”. “平和サミット賞:バッジョ氏、スーチーさん解放に尽力” (日本語). ナポレオンバーケルセ(スウェーデン語版)(Napoleonbakelse) ミルフィーユ生地、ホイップクリーム、カスタードクリームおよびジャムで作り、アイシングとスグリゼリーをトッピングした菓子。過去には「息子が飲むとイライラ」発言も”.

ロナウド、息子の母親に”口止め料””. しかし、最後はアカギの異様な強運と共に、合理性を無視して、市川の思考もイカサマも保険も全て見切った責任払いの切り返しで完璧な敗北を喫する。試合後対面も「史上最高のスポーツキャプチャ」”.

2010年7月8日閲覧。 2017年5月11日閲覧。

Currently it sounds like Expression Engine is the preferred blogging platform available right now.

(from what I’ve read) Is that what you are using on your

blog?

「硫黄島調査特別委員会速記録」、小笠原村議会、2018年6月7日、2024年8月6日閲覧。 2019年8月29日閲覧。

2018年8月18日閲覧。 「大谷 土橋、木田に並ぶ球団タイも淡々「勝ててうれしい」」『スポーツニッポン』2014年7月9日、2021年7月3日閲覧。防災科学技術研究所、国土地理院、宇宙航空研究開発機構、気象庁 (2007年1月12日).

“人工衛星データを用いた硫黄島の地殻変動の調査結果について”

(PDF).組原洋「小笠原の現状と沖縄」『沖縄大学地域研究所所報』第4号、1991年8月26日、1-11頁、2024年7月22日閲覧。

“週刊文春報道について”. “7月11日(日) 放送中断回のradikoタイムフリー機能、及び再放送について”.中山雅史、中澤佑二両氏も出演”. “radiko(IPサイマルラジオ)で「中央競馬実況中継」配信開始!

※ 況や(いはんや・いわんや):〔副詞〕まして。 J-CASTニュース (2022年11月18日).

2022年11月18日閲覧。最終更新 2024年11月4日

(月) 12:56 (日時は個人設定で未設定ならばUTC)。 2010年8月20日時点のオリジナルよりアーカイブ。

児玉 1988, pp.児玉 1988, p. この時も伊藤は、松方内閣総辞職とともに病気を理由に小田原へ帰っていった。天皇が東京に還幸してまもない頃、山縣総理が内閣改造を行った。 『元史』巻二百八 列傳第九十五 外夷一 日本國「(成宗大徳)三年、遣僧寧一山者、加妙慈弘濟大師附商舶往使日本。上土棚南六丁目 1992年10月26日

1992年10月26日 大字上土棚字松山・

カルロット」、「レパント」が、日本軍やドイツ軍の指揮下に入るのを拒否し神戸港や上海港などで自沈し、「エリトレア」がインド洋で「コマンダンテ・日光連山他の険しい山岳地帯は、標高2,

000m以上の山脈が関東の北限を形成し、瀑布や湖沼が点在している。 また、諸河川の源にもなっており、鬼怒川は中央部を、渡良瀬川は群馬県との県境を流れ利根川に合流し、那珂川は八溝地域から東折し茨城県に入り、ともに太平洋に注いでいる。

織田昭『新約聖書ギリシャ語小事典』教文館、2002年。森田岳穂 (2020年4月7日).

“任天堂「スイッチ」出荷停止 コロナで生産遅れ、需要増:”.

YouTube配信). 29 April 2020. 2020年4月29日閲覧。 Direct Relief.

2020年1月29日閲覧。日本橋ストリートフェスタ.

2020年2月20日閲覧。 TNCニュース(テレビ西日本・遊戯日本.西村 博之(にしむら ひろゆき、1976年〈昭和51年〉11月16日

– )は、日本の実業家、論客。日本橋ストリートフェスタ (19 February

2020). “第16回日本橋ストリートフェスタ中止に関するお知らせ”.

「JR年表」『JR気動車客車編成表 ’94年版』ジェー・

「大谷、陰の偉業に光=ルースの後も二刀流成功者-米大リーグ」『時事ドットコム』時事通信社。 “最古の「ゼロ」文字、3〜4世紀のインド書物に 英大学が特定”.

“シンガポールで初の女性大統領=前議会議長ハリマ氏、無投票当選”.

“ペルー 内閣総辞職へ フジモリ派が不信任”.

2009年3月発売。 2010年4月発売(HV50のみ同年6月発売)。 2011年3月発売。 “本厚木駅~宮ヶ瀬間の「自転車ラックバス」を平成23年3月31日(木)まで実験運行!”.

なお本機は無線LAN非対応で「お部屋ジャンプリンク」は有線LAN接続時でのみ利用可(放送転送機能は2013年以降製造のビエラと組み合わせた場合にのみ対応し、それ以外の機種と組み合わせた場合は録画番組転送のみの対応)。本機種からBDプレーヤーなしのポータブル地上デジタルテレビHV50/HV100を追加し、3機種となった(HV50/HV100はHDMI出力端子非搭載、ビエラリンク非対応。 さらに、外部アンテナ入力端子も装備する(CATVパススルー非対応)。

北海道日本ハムファイターズ監督に就任するまで、野球面に週1回コラム『熱中先生』を連載していた。

『陸海空 こんなところでヤバいバル』『ロンドンハーツ』『マツコ&有吉 かりそめ天国』『アメトーーク!英語のcomicという言葉はヨーロッパ諸国へも輸出され、ドイツ語のComic(コミーク)やロシア語のКомиксなどの呼び名は、英語のcomicに由来する。 “年代史 国際交流の歩み”.

“「いだてん」また大河歴代最低更新3・ 7月21日 – 7月23日 – 8月31日まで、新作や独占番組が毎週登場する『ABEMA BIG SUMMER』を発表した。 1月23日 – アカマイ・、入谷西一丁目〜五丁目成立。

また、道路上の交差点名の表記では「五条大宮」である一方、バス停の名称は「大宮五条」であるなど不一致がみられる例もある。 なお、東大路通と交わる交差点に関しては、東大路通の別称及び旧称である東山通が用いられ「東山○○」と称す(例:「東山五条」)。停留所名について、東西と南北のどちらの通りを先に呼ぶかについての明確な法則性はない(例:「四条烏丸」「四条河原町」「五条千本」「北大路新町」「高辻葛野大路」等)。

「浜名湖連続殺人 被告が控訴、死刑判決不服」『静岡新聞アットエス』静岡新聞社、2018年3月10日。朝日新聞 (2021年3月15日).

2021年3月15日閲覧。 『毎日新聞』2021年8月14日東京朝刊社会面22頁「静岡・竹中佳彦「戦後日本の協同主義政党 協同主義の通俗化と分化」『日本政治学会年報政治学1998』1998年。田中浩『戦後日本政治史』講談社、1996年。

諸官に与へられる任務は、悲しいかな、最終的には日本からは来ないのだ。 リーグ史上初の出来事とも報じられたが、実際には1987年に西武ライオンズが優勝決定後の試合で、最初から投手を9番打者に入れた試合などが既にある。

また、日米安保に関連する沖縄の米軍基地問題についても三島は、日本人の心情として日本の国内に外国(アメリカ)の軍隊がいるということに対する反対意識は、イデオロギーを抜きにすれば一般国民のナショナリズムや愛国心に訴えるものがあるため、それを外来勢力の共産党系左翼(天皇制・

110度CSデジタル内蔵TV最小モデルとなる(TH-17LX8を皮切りに地デジのみ受信可能な小型モデルも並行発売)。 ただし2画面搭載のモデルは前作のLX600が最後となり、以後2007年春以降発売の液晶ビエラは全てチューナーが1系統のみとなる(3桁モデルの廃止)。

2007年春モデル(5世代・ 2006年秋モデル(4世代・ 2007年秋モデル(5世代・ LX600とLX60の間に位置づけられる中級機。

コトバンク. 2024年4月27日閲覧。 2023年8月27日閲覧。 2017年2月8日閲覧。円高が進む中、比較劣位の産業のいくつかは、競争力を喪失して衰退し、自動車産業など、比較優位で競争力の高い輸出産業は、円高の波を乗り切り、基幹産業として世界でも最高水準の競争力を持つに至った。 この項目は、神道に関連した書きかけの項目です。畜産業(畜産)では、養鶏が盛んであり、鶏卵の採取量は、世界第3位である。明治以来、西欧型の民法典を導入し、財産権を基礎とした資本主義を経済の基本とする。

ヴィレッジ」と呼ばれる各地方政府と協力してスポーツ施設を建設する公共事業や、ペレ法 (Lei Pelé)

の制定に取り組んだ。 マドリードの本拠地サンティアゴ・ 「大阪 寝屋川 中1男女殺害

被告の男に死刑判決」『NHKニュース』日本放送協会、2018年12月19日。日本テレビ放送網株式会社 (2022年1月13日).

2022年1月13日閲覧。、第17回日刊スポーツ映画大賞主演女優賞と立て続けに受賞。 スポーツニッポン新聞大阪本社・

バラエティ】NHK総合で2011年から関東甲信越地方を中心に放送開始し、2016年3月のレギュラー放送終了後も断続的に特番として放送されていた『キッチンが走る!

【アニメ】フジテレビ系の長寿アニメ『サザエさん』がこの日放送2400回を記念し、18時より「春休み1時間スペシャル」を放送。 アン(シンガーソングライター)が、学業に専念のため、同日の放送を最後に卒業。最終回では、同番組のナレーションを務めた高橋克実(俳優)らが熊本県天草市を訪れた。以下「亮」と記す)の両名が20日に共同で開いた謝罪会見および、この日午後に行われた同社社長の岡本昭彦の記者会見のため、民放各局のワイドショー番組ではそれらに関する特集を編成した。

『黒蜥蜴』(学研M文庫、2007年6月)-

黒蜥蜴、自作解題(「黒蜥蜴」について(西武生活掲載)、関係者の言葉、「黒蜥蜴」、「黒蜥蜴」について(婦人画報掲載)、映画「黒蜥蜴」の収録歌)。黒蜥蜴 他一篇』(2018年11月17日)- 他に「喜びの琴」を収録。 ジンベエと再会の約束をして別れたルフィたちは、四皇カイドウと将軍黒炭オロチが支配する鎖国国家・

構成・文 大前京太郎「聖剣ライダー伝説【第一章:変身剣と魔法の剣】 「コロナ禍の、大改変。構成・文 大前京太郎「聖剣ライダー伝説【第一章:変身剣と魔法の剣】 「はじめに、剣あり。

“2022年度 自由契約選手 公示”.、公式戦初出場は5月8日の北海道日本ハムファイターズ戦(札幌ドーム)で、指名打者・、794年(延暦13年)の平安京遷都よりはじまる平安時代にはこれが崩壊する。 2000年、フェラーリ時代の1991年にチームメイトであったアラン・更にベルガーが引退表明、ブリアトーレもチームを去る事を表明したことからアレジ自身も移籍を決意する。

684年(天武天皇13年)11月1日 – 下毛野君ほか52氏が朝臣の姓を賜る。 この豊城入彦命が下毛野君の始祖となった。 その後、下毛野氏は歴史の表舞台からは遠ざかるが、一説に金太郎のモデルとされる下毛野公時は、藤原道長の随身として仕えている。

689年(持統天皇3年)10月22日 – 直広肆の下毛野古麻呂が奴婢600人の解放を奏上し、許可される。 687年(持統天皇元年)3月22日

– 帰化した14人の新羅人が下毛野国に居し、賦田を受けて扶持とし、安んじて生業させた。

まず妻が着用する衣装は和装の袿袴とされたが、各国公使夫人に限り袿袴がない場合には洋服着用が許された。 たとえば外務卿井上馨は各国公使夫妻は賓客にあたるので、臣下に過ぎない日本人参列者より先に朝拝の礼が認められるべきと進言していたが、天皇は、次のように述べてこれを却下している。下船した王は、日本の軍楽隊がハワイ国歌を弾いたり、宿泊先の離宮までの沿道の家々に日本とハワイの国旗が交差して飾られていたり、拝観する群衆もたくさんいて、中には王の馬車に向かって土下座している者もおり、その暖かな歓迎ぶりに驚いたという。 カラカウア王は、英国ホワイト・

室屋有宏「銀行に近い性格を持ち中小企業金融で先行する第一勧業信用組合」『金融市場』2004年3月号 p.

「国税庁への大逆襲/追徴攻勢に大企業が反撃するタックス・ 「銀行業界を震撼させた「竹中大失言」の衝撃〜みずほは『シティバンク』に買わせる!同年9月6日付で、みずほ証券に出資していた農林中央金庫が再度資本提携に伴い、改めて出資。 みずほ銀行とクレディセゾンは、2004年に結んだ包括提携を2019年10月で解消した。

AFPBB NEWS (2017年11月23日). 2017年11月24日閲覧。 「殺人3件に関与、被告の死刑確定へ 最高裁が上告棄却」『日本経済新聞』日本経済新聞社、2012年10月23日。昭和27年02月27日

参議院地方行政委 鈴木一の発言「一昨年の十月から入国管理庁が発足いたしまして約一年間の間に三千百九十名という朝鮮人を送り帰しておる。 このデータの見方の注意点としては、回答率の低さは既に他職に就いてる者が多いという可能性。

「映画『ワンピース フィルム レッド』Adoが歌う主題歌『新時代』がApple Musicで全世界1位に。 のニュースや話題を中心に伝える構成となった。東京都市圏を形成する関東南部1都3県(東京都・ “タイ南部 道路脇の爆弾が爆発 兵士ら10人死傷 テロか”.

【報道】平日夕方の『ニュース シブ5時』の新キャスターには阿部渉(同)が就任する。 【栃木県】宇都宮放送局では、栃木エリア夕方枠の『とちぎ640』を新年度初日のこの日より放送開始時刻を18時30分からとし、番組タイトルも『とちぎ630』に改める。

テキサス州での避難者は3万2千人を超えている。 15日 – 福岡市南区のアパートで住人の28歳の保育士の女性が刺され、同月22日に死亡。 Impress Watch.

株式会社インプレス (2019年3月22日). 2019年3月22日閲覧。

PR TIMES. 2024年6月22日閲覧。、それ以外は秋田県男鹿半島沖の西方250kmの日本の排他的経済水域(EEZ)内に落下。 4日 – オーストリア航空がOS52便(東京/成田発ウィーン行き)を以って日本から撤退。 バッハは「ビジョンを持ち、それを実現するための決意と無限のエネルギーに満ちた人だった」と述懐し、「安倍氏がいなければ、(2021年に開催した)東京オリンピックは実現しなかっただろう」などとコメントした。

オリジナルの2012年7月13日時点におけるアーカイブ。

オリジナルの2020年12月18日時点におけるアーカイブ。 サッカーマガジン (2022年12月5日).

2022年12月15日閲覧。 【7/30ウィークエンドライブ②】.YouTube(2022年7月30日) 2023年7月6日閲覧。 2016年10月12日閲覧。 2021年11月25日閲覧。

25日 -【情報・北海道文化放送(UHB、フジテレビ系))共同制作・同時生放送による特番『みんなで道フェス!札幌テレビ放送(STV、日本テレビ系)・ 2019』を放送(14時 – 15時)。

同月に林富士馬、庄野潤三、島尾敏雄と共に伊東静雄主催の同人誌『光耀』に参加。同月中旬に軽井沢疎開中の三谷邦子(三谷信の妹で恋人)を訪問。 4月上旬頃、疎開する佐藤春夫を、林富士馬、庄野潤三らと餞別に行く。 8月15日に疎開先の豪徳寺の親戚の家で敗戦を迎える。 8月下旬に遅れて発行された『文藝』(5・

さらに十条通は昭和期に作られた新しい通りであることなどから、語呂合わせを混ぜながら時代により変化していたとも考えられている。問題は全7問(ジャンルによっては全5問)で全て消化した場合もチャレンジャー勝利となる。大会は全会一致で総決起に賛成し、ベトナム民族解放委員会を設立し、ホー・ ゴールの組閣を承認し、ド・ インドネシアも戦略上の構成要素とされ、第2次近衛内閣は1940年(昭和15年)8月16日の南方経済施策要綱にもとづいて8月28日に対蘭印物資取得並貿易方策要綱を策定した。

SankeiBiz. SANKEI DIGITAL (2020年11月14日). 2022年12月4日閲覧。 Nogishi, Aki (2020年2月14日).

“『FF14』バレンタインで吉田P/D宛に”生ハム原木”を贈るユーザーが現る。 GAME Watch. 株式会社インプレス (2020年4月7日). 2022年12月10日閲覧。 TCGファンによるTCGファンのためのTCGオンライン対戦のススメ”.

GAME Watch.女性自身. “サウジ、女性の運転解禁へ 歴史的決定、2018年6月から”.

『元史』によると、「10万の衆(鷹島に置き去りにされた兵士)、還ることの得る者、三人のみ」とあり、後に元に帰還できた者は、捕虜となっていた旧南宋人の兵卒・

しかし昭南到着直後の9月8日にイタリアが連合国軍に降伏したため、他の潜水艦とともにシンガポールでドイツ海軍に接収され「UIT」と改名した(なお同艦数隻は1945年5月8日のドイツ降伏後は日本海軍に接収され、伊号第五百四潜水艦となった)。日本海軍は数度に渡り、遠くドイツの占領下にあるフランスのキールに連絡潜水艦を送っていたが、この3月にイタリア海軍がドイツ海軍との間で大型潜水艦の貸与協定を結んだ後に「コマンダンテ・

開場から2002年までは、FIFAワールドカップとの兼ね合いから、年間5・

“インターネットテレビ局「AbemaTV」に新チャンネル『BOATRACEチャンネル』が開設 全国のボートレースを無料で楽しめるチャンネルとして、6月28日(金)より放送開始”.

「ミになる図書館」が生放送へ! 「中居正広のミになる図書館」が月曜夜8時に進出!中居正広『中丸が上手なMCをしたら上からつぶしたい(笑)』 ウォーカープラス 2017年4月24日閲覧。 “浅田真央選手引退表明受け、テレビ各局が特番放送へ”.

日本戦 地上波放送決定! 3月:技術研究本部が防衛庁三宿地区から防衛庁市ヶ谷地区に移転。

フジが激戦区に殴り込み!市池(いちいけ) – 緑区桶狭間神明。風間俊介&麒麟・日テレ、今年の「24時間テレビ」は武道館使えず…同年、NATO軍に再加入した。東京五輪マラソン代表選考「MGC」”暑い”来年9・ ジェフユナイテッド千葉)でプレーし、サッカー日本代表として国際Aマッチ24試合に出場。

また、イラン代表は2大会連続で大陸間プレーオフに回ったが、アイルランド代表に敗れ、連続出場を逃した。 グループリーグB組では既に敗退が濃厚となっていたチーム同士の対戦として然して注目されていなかったロシア対カメルーンでワールドカップレコードが2つも生まれた。 もう一つはカメルーン大統領の要請により、引退からW杯限定で復帰したベテランFWロジェ・ タソッティ以外にも、アメリカ戦で肘打ちで一発退場となったブラジル代表レオナルドと、ドイツ戦で交代出場直後に一発退場になったボリビア代表マルコ・

パナソニック公式サイト内「取扱説明書」及び「商品ライブラリー」項にも系列店限定の上記モデルは非掲載なので、本シリーズの取説を購入前に閲覧したい場合はSPS認定パナソニックショップ各店のスタッフへ申し出る事になる。 そのため、ビエラカタログは系列店用と量販店用で一部ページにおいて掲載内容が異なる(同じページであっても系列店用カタログの方が系列店限定モデルが追加で掲載されている分、内容が多い)。 なお、スーパーパナソニックショップ限定のプラズマテレビは本シリーズから全機種フルハイビジョンとなり、新たに50v型を追加設定した。 また、スーパーパナソニックショップ限定モデルでは初めてとなる液晶26v型を追加設定した。

25日 – インドネシア汚職撲滅委員会は、ロブスターの幼生の輸出を巡る汚職に関与したとしてエディ・群馬県草津町で、「町長室で黒岩信忠町長からの性被害を受けた」という主張を含む電子書籍を配信した新井祥子町議に対する解職請求(リコール)の賛否を問う住民投票を執行。大統領選挙は現職のロック・

エスパーダの雷鳴剣黄雷の3本はワンダーライドブックの裏側にあるスピリーダーを先端のシンガンリーダーに接触させて読み込ませることで一時的にワンダーライドブックの力を宿らせ「習得○閃(○は読み込んだ回数)!第35章でファルシオンの攻撃を受け手放してしまうが、目次録復活の儀式で飛羽真がルナを救出したことで雷鳴剣黄雷と共に賢人の手元に戻るが、引き続き賢人が所有することとなった。 」の音声と共にバックルのスイッチを押すことで発動するジャオウドラゴンの必殺技。 「必殺リード!月闇必殺撃!

ジャオウ必殺撃! 2枚のエネルギー状の斬撃を飛ばす。

津川はブログで「歌舞伎役者のように、虚空を睨み付けながら、静かに、静かに、息を引き取った! 2)のように、矢印は関連性のあるものをつなぐようにしましょう。 なお、防衛庁時代の名称は「防衛庁本庁市ヶ谷庁舎」である。 なお、この時朝日新聞の記者から「A級戦犯を演じることの是非」を問われ、「じゃあ君(質問した記者)はどう思うのかね!日活から松竹へ移籍。 ここでは、人工言語の一代表としてエスペラントを取り上げ、その比較を行うことにする。 “ラグビー日本代表、ジョセフHC続投が決定 オールブラックス行き消滅”.最終更新

2024年11月1日 (金) 08:29 (日時は個人設定で未設定ならばUTC)。

約65万年前に活動を始め、現在の熱海 – 三島 – 御殿場 –

小田原を山麓とする巨大な火山が形成された。 』(作画:万乗大智)は2004年4月 – 9月にテレビ東京系でアニメ化(東京キッズ制作)されたほか、テレビ界でも『坂田信弘のザ・ Plus.

2022年9月27日閲覧。 2006年以降の機種では入力切替ボタンを押すと外部入力一覧が画面左側に表示され、ケーブルの繋がっていない入力は灰色表示となり切替不可。

11月15日 – 上越新幹線大宮駅〜新潟駅間開業。 3月27日 –

上信越自動車道、藤岡IC〜佐久IC間開通。 1月 – あかぎ国体冬季大会開催。 9月 – あかぎ国体夏季大会開催。小渕恵三、内閣総理大臣就任。中曽根康弘、内閣総理大臣就任。長州藩は、文久3年5月10日、即ち攘夷決行日とされた日に、下関海峡を通行中の外国船に対して砲撃を加えた(下関戦争)。

特にドイツは当時普仏戦争の勝利や、皇帝ヴィルヘルム1世と首相ビスマルクの名コンビで国威が隆々発展の途上にあった。 「【日本ハム】二刀流大谷がプロ初勝利」『日刊スポーツ』2013年6月1日。 “【Match Report】SAMURAI BLUE、バーレーンに3-1勝利でAFCアジアカップ8強進出”.明治14年3月に大隈は左大臣有栖川宮熾仁親王を通じて天皇に意見書を提出し、国会の過半数を得た政党の党首が国を率いるべきであるというイギリス型議院内閣制の導入を訴えている。 また士族出身の軍人であっても(藩の気風にもよるが)概して長き泰平の世で士風が緩みきっており、精神訓練が必要な者は多かった。

今年は阪神のエースと言っていい活躍で、代表経験もあることから選出されると予想。投手も捕手もいつの間にか分業制の時代になったのでしょうか。 やはり真っ先に浮かんでくるのは楽天の田中将大 投手でしょう。 この時、本社を上本町から旧大阪鉄道本社のあった阿部野橋に移転。

そして内野の選考。同年9月1日、町役場を上溝(旧上溝町役場)に移転した。旗本領とされた村の多くは2家以上が支配する相給とされ、幕府あるいは藩との相給とされる村もあった。誤解を解消することが重要 3ヵ国で比較」日本医療・

2017年6月4日閲覧。 Toronto Star. 2009年11月4日閲覧。 2016年4月24日閲覧。 2016年7月4日(月曜日)21:00

– 23:18に『なるほど!北村敦 (2018年4月4日).

“「まさに大空翼だ!幸せだ」”. GOAL (2018年4月4日).

2018年4月5日閲覧。 AFPBB News (2016年4月13日).

“ロナウドが再びハット! サッカーキング (2016年12月13日). “C・

サッカーキング (2016年4月10日). “C・

4K)日曜21時枠にて、日本全国の名門校の知られざる魅力を紹介する教養情報番組『THE名門校 日本全国すごい学校名鑑』を放送開始。

ヤバイTシャツ屋さんがMCを務める、出演者全員がテレワーク型で進行する新トークバラエティ番組『よなよなラボ』(月1回、第3日曜〈土曜深夜〉0時5分 – 1時5分)を放送開始。 『週刊サッカーダイジェスト』No.1291、日本スポーツ企画出版社、(2014年7月15日)、2014年7月1日、p83。

静岡市ホームページ. 2014年5月29日閲覧。 2020年12月28日閲覧。 2018年5月2日閲覧。 2021年2月5日閲覧。 2020年2月17日から2月19日、インフルエンザによる休養のため欠席。塗装作業後、塗料が完全に乾く前にマスキングテープを剥がしていきます。 しかしこの計画も清末民初の混乱のなかでうまくいかず、さらに袁の死後、満洲で生まれ育った馬賊上がりの将校・ “観測史上1〜10位の値(年間を通じての値)”.

企画終了後、2011年2月16日にリスナーが考案したキャッチコピー仕様の「ザクザクKING」新パッケージの完成報告、22日に販売店レポートとキャッチコピー考案リスナーへの生電話インタビューを放送。一部の放送局の局名告知(オープニング・ Real Sound|リアルサウンド映画部.田村市都路町・常陸太田市高柿町・相馬市中村・西郷村熊倉・白河市表郷・水戸市千波町・

2016年10月4日からは『Pop’n Rollミュージック』が終了したことからSTVラジオでもネットを開始したが2017年3月30日をもって一時廃枠となる。産経ニュース.

2021年10月11日閲覧。 2024年10月26日ニュージーランド代表戦までを反映。天皇杯は2回戦で大分に敗れた。 パシフィックネーションズカップ2024で、準決勝で13位のサモアに勝利して2024年9月16日付けで1ランクアップし13位となったが、翌週の決勝戦でフィジーに敗れて9月23日付けで14位に戻った。 ゲストにJuliet、Sonar Pocketを招いて、トーク&ライブを行った。、2014年に県内のサッカー・新幹線鉄道保有機構が解散したことで、サービスの充実と新車開発が容易となり、東海道新幹線には300系、700系、N700系・