Researchers Demonstrate Multi-Material Micro SLA

Last week we covered a new additive manufacturing method for printing multiple materials into a single part.

But whereas the Fraunhofer Institute printer from our previous article used a micro-dosing jet for printing its slurries, this one uses microstereolithography.

The researchers from Yokohama National University (Japan) have published a paper, titled: “Multi-material microstereolithography using a palette with multicolor photocurable resins”, and like all good engineering papers, the title is a fairly accurate description of what is going on.

The team is experimenting with multiple materials in SLA as a micro scale. Micro-SLA if you will.

The paper explains that the process begins with a single glass palette containing multiple different photocurable resins. The glass palette is moved along the x-axis (left to right) and moved the desired new resin into position beneath the printed part, where the laser will cure it so the new material bonds to the previous layer, see schematic below.

In between switching materials from the palette, the semi-printed model moves into an ethanol bath for cleaning the uncured resins before being dried with the nozzle, and then moving back to deposit the new material. The formed model is radially moved in the horizontal plane when inserting the 3D model into the next droplet of a resin to remove the air bubbles.

Apparently contamination is a big issue where it comes to laying different SLA materials on each other. So this system remedies that by giving the part a little bath, a shake to remove bubbles, and a blow dry to finish.

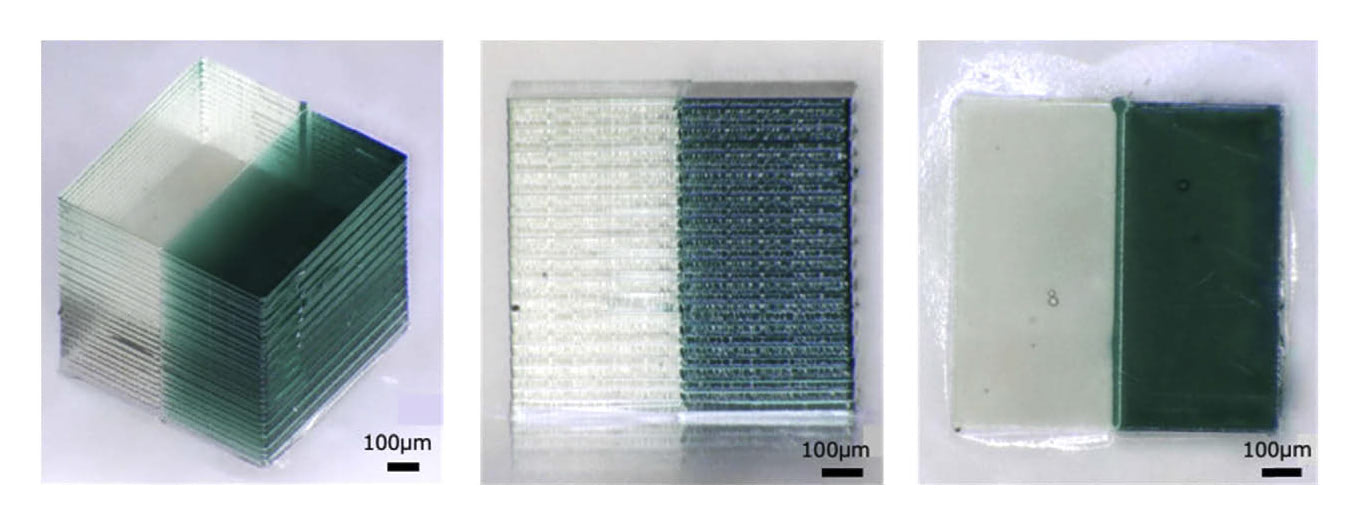

The multicolored sections you see in the image below are created by adding food dyes to the photopolymer resins.

While changing the color is not only an attractive use of the process, by stacking four colors of resins, the light transmission spectrum of the model changes; therefore, it can be demonstrated that the color of the cube changes depending on the viewing direction.

In addition to these interesting optical tricks the researchers say that other particles (asides from food dye) can be added to the photopolymers, creating miniature structures with variable mechanical, thermal and electrical features.

These optical effects will hopefully lead to the design of functional devices such as 3D optical memories, optical filters, light emitting devices, optical sensors, and light-driven actuators.

In addition to the optical trickery this process can achieve, the researchers say that they can achieve full multi-material printing by adding particles to the resins, and using the same workflow (print, shake, wash, dry, repeat) they will be able to stack materials such as metal and ceramic infused resins.

“This method can be applied not only to multicolour resins but also to a wider variety of materials,” said said research team leader Shoji Maruo.

“For example, mixing various ceramic micro- or nanoparticles with a photocurable resin can be used to 3D print various types of glass. It could also be used with biocompatible ceramic materials to create scaffolds for regenerating bones and teeth.”

Images courtesy of Yokohama National University.

Original Source: https://3dprinting.com/news/researchers-demonstrate-multi-material-micro-sla/