Tested: colorFabb Filaments with Active Foaming Technology

3D Printers continue to improve year after year, but the fundamentals of the technology haven’t really changed much over the years.

What I find to be more exciting is the new materials that are constantly being introduced to the marketplace, offering new and useful capabilities for your existing 3D printer hardware.

Introducing Colorfabb varioShore TPU and colorFabb LW-PLA

As a fine example of the intriguing capabilities new materials can offer, colorFabb recently introduced two new filaments that feature an active foaming technology, allowing the creation of lightweight, low-density parts.

Colorfabb varioShore TPU

colorFabb created a flexible TPU material called varioShore TPU that uses active foaming technology, to allow for variable shore hardness, even within the same print.

Although the weight reduction of varioShore TPU is not as significant as LW-PLA, the weight of the overall print is noticeable and can make the difference for prints where weight matters.

For example, at 3D Universe, they’ve been working on developing 3D printed respirator mask designs. They found that printing these masks in varioShore TPU results in a mask that is lighter, softer, more flexible, and more comfortable compared to those printed in standard TPU.

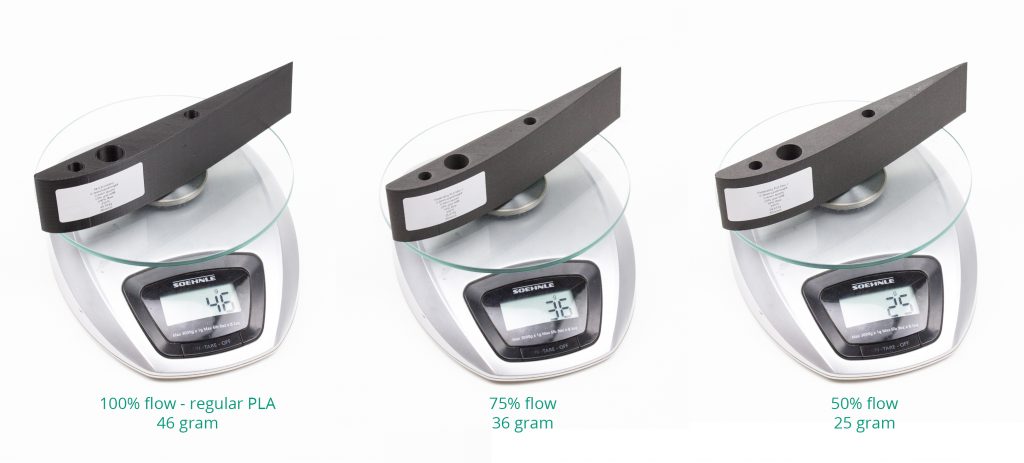

Left: BE Mask, printed in standard TPU, weighing 44g. Right: BE Mask, printed in colorFabb varioShore TPU, weighing 26g

What I love about this material in particular is that the active foaming technology doesn’t just result in a lighter part. It also produces a noticeably softer part. So if you’re looking to produce a part that will be more comfortable, such as a handle bar holder, shoe insole, etc., this material offers a significant advantage.

colorFabb LW-PLA

Using the same active foaming technology featured in Varioshore TPU, LW-PLA will start foaming at around 230°C, increasing its volume by nearly 3 times. Users can decrease material flow by up to 65% to achieve lightweight parts, or use the expanding properties to effectively reduce print time by using big layer heights or single extra thick perimeters.

They tested this material using the 3D Benchy to see for ourselves if the material would live up to the marketing claims.

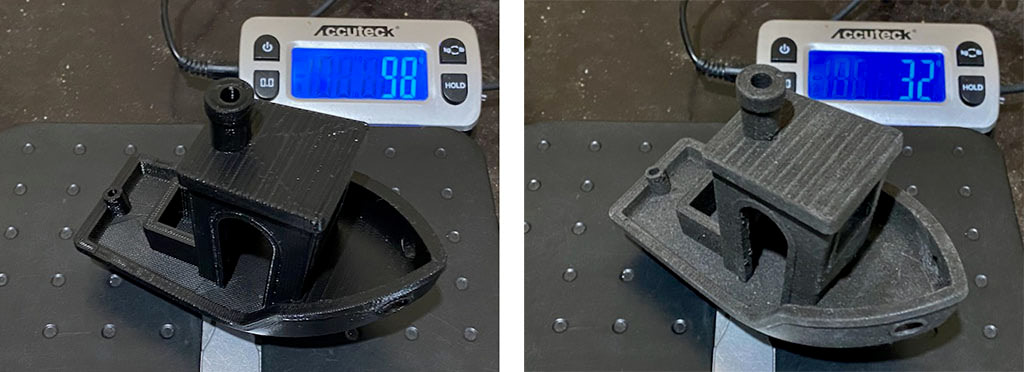

First, they printed the model in standard PLA, using a 50% infill. As you can see below, the resulting model weighs 98g.

Next, we printed the same model using the same 50% infill with Colorfabb LW-PLA. In order to maximize the active foaming effect, they used a high printing temperature (255°C), and they reduced the flow rate to 35%.

The result, as you can see below, has a very different surface finish compared to normal PLA. It’s a matte finish, unlike standard PLA, which is usually somewhat glossy.

Left: Standard PLA with 50% infill and normal settings. Right: colorFabb LW-PLA with 50% infill, printed at 255°C and a flow rate of 35%.

As shown above, the same model printed in LW-PLA was a third of the weight as the one printed in standard PLA, even when the same infill density was used.

The same active foaming quality of this material can also be used to print items more quickly by using thicker layer heights. Normally, your maximum layer height is around 75% of your nozzle diameter. So for example, with a 0.4mm nozzle, you wouldn’t want to use anything thicker than 0.32mm layers. But by taking advantage of the active foaming quality of LW-PLA, you can print with layers up to 0.6mm thick using a 0.4mm nozzle.

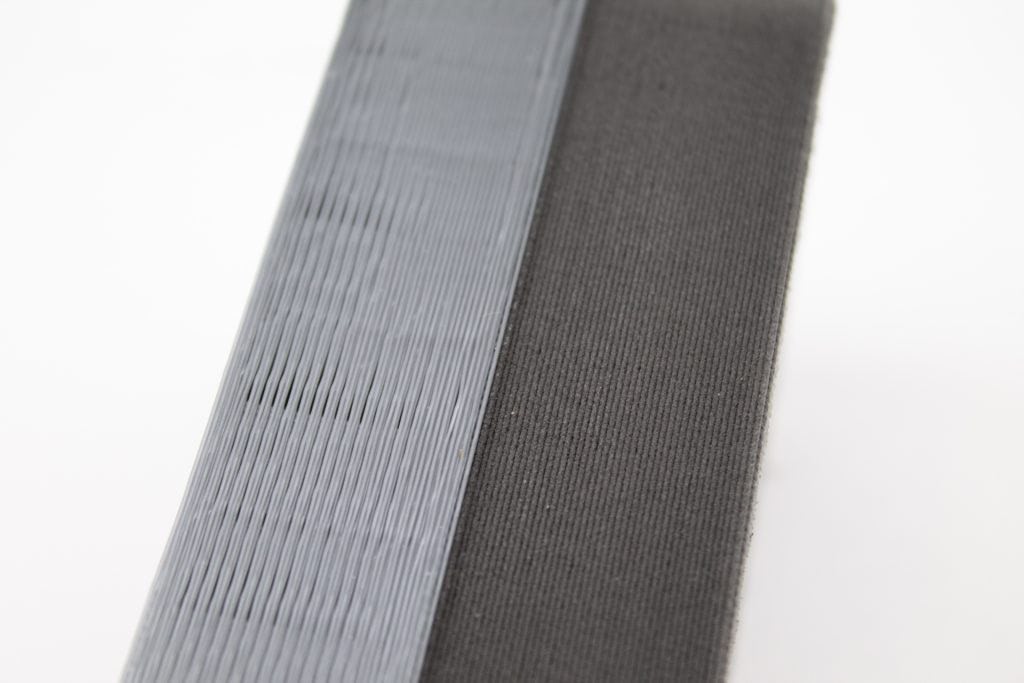

Left: regular PLA with a 0.6mm layer height and a 0.4mm nozzle. Right: colorFabb LW-PLA shows the expanding properties enabling 0.6mm layer height from a 0.4mm nozzle.

What you’re seeing in the image above is that trying to print normal PLA with a 0.6mm layer height with a 0.4mm nozzle results in gaps and imperfections because you can’t push that much material out of a 0.4mm nozzle. Due to the foaming property of the LW-PLA, the 0.6mm layers shown on the right are nice and clean.

It’s been a lot of fun trying out this exciting new material. Pick up a spool for yourself today!

Original Source: https://3dprinting.com/filament/colorfabb-launches-filaments-with-active-foaming-technology/